-

Posts

7,355 -

Joined

-

Last visited

-

Days Won

32

Content Type

Profiles

Forums

Calendar

Everything posted by 5523Pathfinder

-

I just found this while cruising on my ASIST computer. Maybe help answer some questions.... '90-'95 Pathfinder: Remaining fuel level specifications The following specifications reflects a range for the amount of fuel remaining in the tank when the gauge points to 'empty' and when the low fuel light is 'on': Gallons remaining when fuel level reads 'empty' approximately 1.5 to 2.4 Gallons remaining when low fuel light 'on'. approximately 3.0 to 3.2

-

Heres a idea from my ASIST computer... Symptoms: Speedometer has excessive needle vibration and noise at speeds above 50 mph. Speedometer, cable, and drive pinion might have been changed but did not affect the incident. Field fix: With the vehicle supported safely on a rack and the rearwheels off the ground remove the speedometer head and watch the speedometer cable while running the drive line at about the incident speed. If the cable is noisy and chattering in movement the nylon drive gear in the transfer case may have turned on the output shaft and become oval-shaped. If the gear is deformed, replace it.

-

-

Heres an idea for wheels if you like. This is what mine look like just after I installed the hubs last spring.

-

Swapped in or factory?

-

I want to say is was 93 when they starting using disc. Its so hit and miss as to which ones have it. If its an LE, i believe they all have it. The 94 I worked on yesterday did.

-

Sounds like the printed circuit may be getting power when its not supposed to. You may want to pull the cluster and check the back of it for any damage for debris.

-

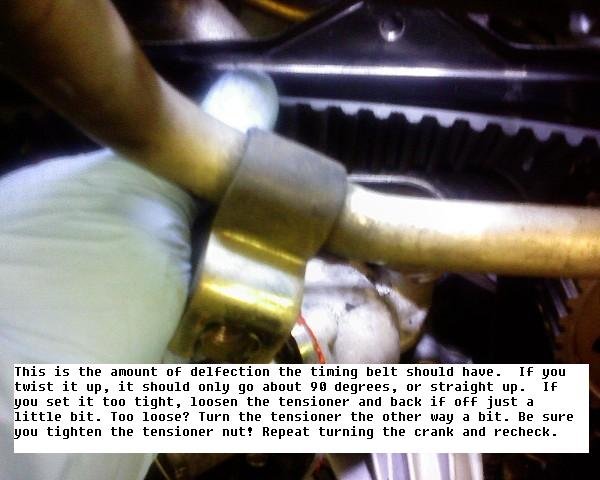

Man, that would be insane! Even with the lifters removed(which are hydraulic), the cams are still not going to move. The tension is going to change continuesly. Thats why you set the tension as I described. The factory manual wants you to set the tension with a pull gauge, but 10 years of doing timing belts, this is the easiest way to do it. And, I have never heard of that procedure before! What a gigantic pain that would be.

-

Here's a little addition. This is what the timing belt tensioner position should look like once is has been properly set up.

-

Make sure you didnt pull one off for rear disc brakes and you dont have them. It wont work correctly. Like MZ said, did you bleed everything correctly and get the air out? Yeah, I wouldnt trust a J/Y master cylinder, unless you rebuilt it.

-

Is the feeling continual, or just for a second? When you push in the clutch, the throwout bearing contacts the pressure plate springs, but then rotation is stopped. When was the clutch replaced? Im thinking wear on the pressure plate springs.

-

A little bit of metal is ok. What you are worried about is chunks or something that just doesnt look right. Usually a small amount of metal "flakes" will collect on the magnet. You should be able to make out the magnet when you pull it out. Hey, keep a camera handy and take a pic and show us, maybe that will help.

-

Try disconnecting the air flow meter and running it in fail-safe. Does it then still act up?

-

NPORA Truck Of The Month - January 2007

5523Pathfinder replied to Pezzy's topic in Truck of the Month

:bow: to the Queen! -

Mmmm.....patrol, man I wish we had those in the states. The terrano/pathfinder has been quite capable for me. I guess it depends on what you do with it and how it works for your needs. I have made jaws drop offroad because they cant believe a Nissan could do that!

-

Right off the bat is sounds like a throwout bearing. When was the clutch last replaced? It could also be one of the bearings in the manual transmission itself. I get noise in mine too until its warm. You may want to check the fluid in the trans itself. Maybe its clutch time.

-

Ok, pretty much everthing from here is reassembly. Make sure to check your hoses and belts. If anything is out of order, fix or replace it now! This job isnt that difficult if you have some mechanical skill. It will always be a good idea to have some kind of repair manual near to reference as needed. I hope this helps and I am glad I could do it. If there is anything that need clarification, let me know. If someone wants a different picture of something, let me know!

-

Once you've set the tension and back to TDC, you need to check that belt tension. Give the belt a twist and it should not go any further than 90 degrees. Any more than that and I will make noise. A little less, or tighter, is ok, but it may make noise also. The closer you get to a half twist the better!

-

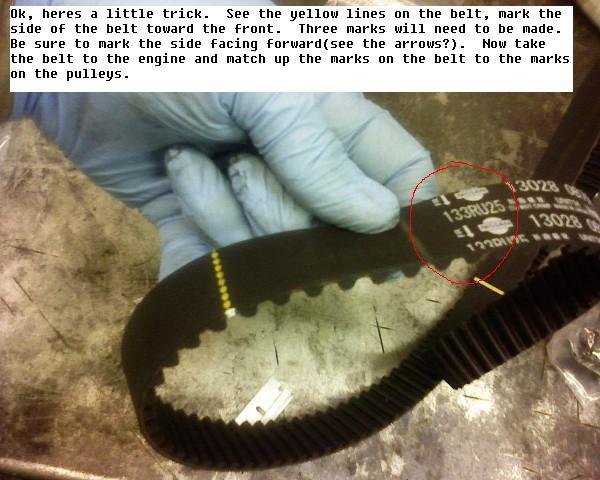

When the paint is dry, install the belt onto the pulleys. If you marked everthing right, the marks will all line up. You need to set the belt tension by turning the tensioner counterclockwise to about the 5:30 position. It lines up with the lower oil pump side, almost a straight line. Follow the instructions in the photo...

-

Heres a quick tip...use that marking paint that you used on the cam and make marks on the side of the timing belt.

-

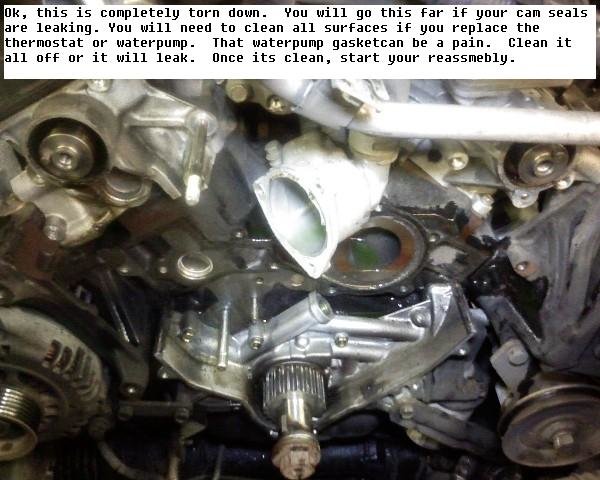

Now, if you are only replacing the timing belt, your work is done. But many of us know thats usually not the only thing your gonna do. Check that tensioner for noise or play. Check under the water pump at the seep hole for leakage and check the drive shaft for play. Check for leaks from the cams seals or the coolant plug on the 3.0. When was that Thermostat replaced? Now is a good time to replace what you want. The camseals can be replaced by removing the bolts on the cams, bolts on the rear cover and remove the seals. Upon reassembly, if the cams move, just line up your marks. DO NOT TRY TO FORCE THE CAMS IN EITHER DIRECTION! The waterpump is as easy as removing the bolts and pulling off the pump. Watch your feet as coolant will come down, grab a pan to catch it. Use your scrapers or spayable gasket remover to remove the waterpump gasket. Make sure everthing is nice and clean before reinstalling. Dont overtighten the pump bolts, is only aluminum! Thermostat is the easiest. 3 bolts, give it a tap and remove it from the housing. Clean all of the silicone from the housing and pipe snout. Install the t-stat with the bleeder valve at the top. You will probably use silicone to reseal, it works best but some have gaskets. The belt tensioner is removed by loosening the nut completly and sliding off the stud. Check that stud for tightness and integrity. Swap the spring to the new tensioner and reinstall. The spring arm will need to rest against the smaller stud and then turn it clockwise back to 9 o'clock. Here is what it looks like completly torn down...

-

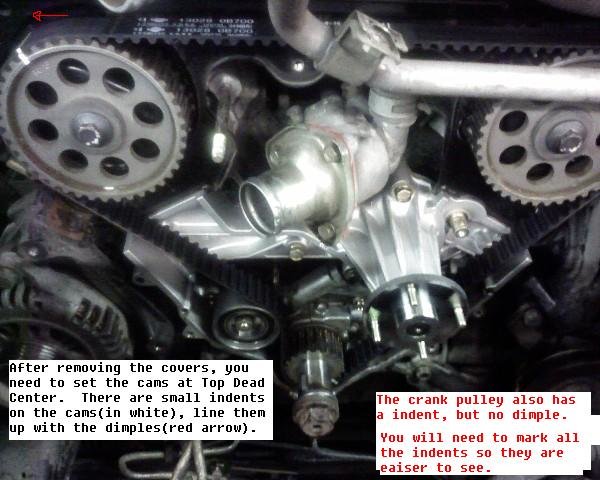

So now you should have your timing belt covers removed. You will need to set the cam gears at Top Dead Center. It may help to clean all the gears and find the indents with letters LH and RH below them. Also find the dimples on the rear cover and note where they are at. Your marks will look something like in the photoafter you set it at TDC. A dab of white paint or highly visible marker on the indents and dimple helps alot! You can now loosen the tensioner pulley nut a half turn or so. You will need to install a hex key that is 5mm. Turn the tensioner clockwise to remove tension. You will only need to turn it to about the 9 o'clock position depending on tension. Now you can slide the belt off.

-

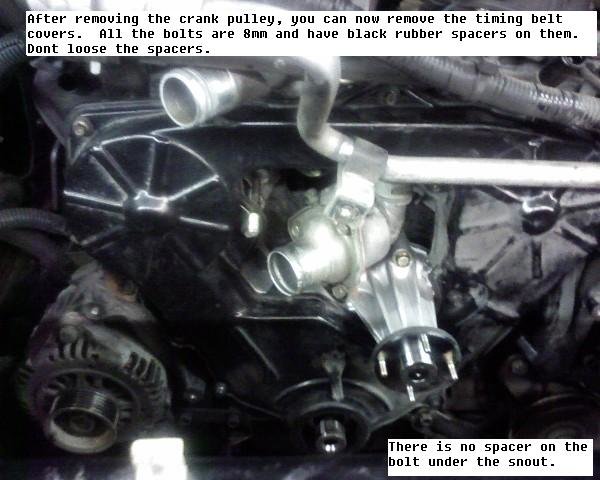

Now you should have somthing like whats in the picture. **R50 owners** when you remove the upper timing cover, the A/C line will be in the way. This will take some time, but you can lightly pull up on the line while jockying the cover out. DO NOT PULL TO HARD!!! If the A/C lines breaks, you have a new mess to worry about, refridgerant will come out! *this pic was taken after I reassembled, yours will not look as clean

-

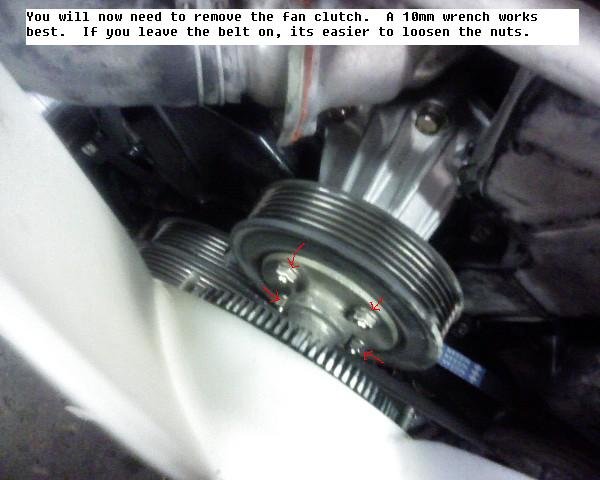

After removing the belts, there is a pcv hose that needs to be disconnected. There are 2 10mm bolts holding it to the upper timing belt cover, remove them. Grab your pliers and release the clamp on your left and pull the hose toward you. Slide it up over the upper coolant pipe to give better access. Then its time to remove your crank pulley. Get that big socket and breaker bar. You will need to block the engine from turning over by removing the starter and blocking the flyhweel, or if you are a manual transmission, let the powertrain do the work for you. I have seen guys use a strap wrench to hold the pulley and someone else loosen the bolt. You may need to figure a way on your own. If you are lucky enough to have air, be glad! Then use the puller in the picture to pull the pully off the crank snout. The smaller bolt treads I believe were 6mmx1.00. WD21 owners just remove two bolts from the front of the pulley to install tool. R50 owners will need to find the holes and install the tool.

-