-

Posts

1,140 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Calendar

Posts posted by andreus009

-

-

because they don't smell new

-

Uh...based on my experience, the the t-case disconnect isn't terrible but it is awkward to drop due to its weight distribution. Its even more awkward to get back in place for the same reason and cause you have to align things properly to get it back together.

Also, not sure about the access when you get it off either. Unfortunately, I didn't have a lot of reason to look in detail at the tranny cause I was focused on working on the t-case at the time.

-

So what do the lights on the dash do when you go to start it? Dim? Go out completely? One thought is a bad connection at the battery. Sometimes the connection is good enough to turn on dash lights and such but not good enough to give power to solenoid/starter. Also, bad battery can cause this. Have you tried jump starting it?

A manual transmission will have clutch switch..which means it won't turn over if the clutch pedal is not depressed. As I call there is actually a little plastic piece that goes in a hole on a tab on the clutch pedal arm that actually pushes the switch. I had this piece of plastic disintegrate due to age so that when I pushed the pedal down the protruding part of the switch went right through the hole so it didn't activate the switch and I couldn't start it. I replaced the plastic piece with something I had on hand and everything worked fine again.

This is by no means an extensive list of all things that could be causing your issue. There are other threads out there about starting/starter issues that may help with other ideas.

-

I know back some time ago....years...I pulled it down and englarged the openings for larger speakers. I think it was 6x9 from Polk Audio but it's been a while. It still looks factory.

-

I third the timing check. Based on personally experience. Was driving to an off-road meet and the thing was running fine for about 20+miles. All of the sudden the engine just basically lost power and died. Coasted to the side of the road and looked under the hood. Couldn't find anything apparent. Cranked it over and it would just barely start and then sounded real sick. Got it back home and did some more checks but couldn't find it myself. Figured it was something major so I took it to the local dealer since i figure the have the better diagnostic equipment. Anyway...the short story is that the timing/distributor had some how gotten out by ALOT. So much so they asked me if I had had the distributor out for any reason. I hadn't. They reset the timing and it's been running fine ever since.

-

I personally found that for highway driving the rear sway bar was sufficient to keep it stable. I'm basing that on a 500 mile 70+mph trip. And that was with the original bushings that had about 190k miles on them. I'm not saying I didn't notice that it was not there, but the change wasn't sufficient to cause me concern.

I have both off right now and there is a lot of body roll so I would not try to highway drive it without one or the other sway bar on.

-

Yes, I believe it was the PCM version. I'm pretty sure the issue was the underhood temperatures affecting the electronics because when it cooled down it worked fine. It was too much work/rework to install it in the cab. My hats off to you on your diligence.

BTW, in hind sight the controller was almost pointless in FL because the AC runs nearly all the time which means the controller defaults to both fans full on. LOL. Live and learn.

-

Had similar issue with a SPAL dual fan controller. It didn't like the under hood heat in slow moving situations. Pulled it out and now just use manual switches now.

-

Good Man! There aren't too many known failure points and I'd argue that all have been discussed here so looking around is well worth the effort. Here is a basic issue list that may or may not apply to you. Auto tranny cooler, manual tranny fill level, manual tranny GL-4 only, frame rust, body rust, exhaust burn under drivers foot, tension rod bushing, center link and idler arm being front end weak points, fuel rail hoses leaking, liter tap, not changing the timing belt and WTF is up with the oil filter location?

B

BTW, good call on outlining some of the common issues to check into on these rigs.

-

As long as you don't have much rust or none are broken sub-surface in the head, you won't have much problem removing them with the right tool (I used two old nuts counter torqued) and if you do one, do all, especially if you are installing headers. Headers won't put more strain on them, but if you go that far, go all the way!

B

Guess I was the unlucky one. All 3 of mine were at the surface or sub surface.

-

Oh yeah...on the over filling of the tranny be aware of the gear oil you use. That is another gotcha. Alot of the newer oils have additives that eat the brass synchros. The safe bet I hear is RedLine. RoyalPurple is safe too but $$$.

I think this link covers the gear oil in the tranny subject pretty well

http://www.nissanpathfinders.net/forum/index.php?showtopic=31943&hl=%2Bgear+%2Boil

-

In kind replacements will probably crack/break like original. Get the upgraded studs or replace with a stronger bolt like others have done. I believe (don't quoute me) some have used the metric equivalent of grade 8 bolts instead of studs. I'm sure someone can chime in on what kind of bolt they used instead of the studs. Personally, I went with the studs but they are a bit pricey as I recall.

While you are at it I suggest/recommend you replace all studs. Extracting studs can be a major PIA and you don't want to have to go in and do it again. 2 out of 3 went fairly easy for me. The 3rd..well lets just say part of it is still in there and I had to tap what I could for a smaller stud. Key trick with the extractors is to be sure to get them on center (easier said then done). Also, before you even start soak thinks with penetrating oil. I know there is pinned write up on the subject of replacing these studs. I followed it and came out OK. The problems stud was just bad luck and bad access.

-

1

1

-

-

Are you aware of the manifold bolt breakage issue?

-

I got the cermic coated headers from 4x4parts.com. The don't specifically say it on the website by they are by Pacesetter...or at least they were. So far they have held up pretty well and don't show any signs of rusting. Of course they are a good deal more $$ then the plain painted ones but as B says...the paint will flake and then you got rust.

That was the positive side. Now the negative. I was one of those people that had a difficult time installing them. Biggest problem was fitting the cross-over pipe to the two headers. I had to use ratchet strap to pull the ends of the headers closer together to get the cross-over to go on and also ended up triming a bit off the end of the passenger side header. Maybe my order of assembly operations was off a bit. I tightened the headers to the block first and then tried to fit the cross-over pipe. Maybe if I had left some looseness at the head, fit the cross-over, and then final tightened it would have gone better.

-

I know I don't visit it much, but I'd like to thank all the folks that keep NPORA up and running. You guys/gals do an outstanding job. Thank You!

-

I found that the back sway bar had more control over body roll then the front. I hardly notice the front one missing even with my worn out bushings on the rear one. I drove all the way to NC at highway speeds without any issues. Also, it is easier (in my opinion) to quick disconnect the rear than the front. Anyway..that's my two cents. Not that you need them, but could save you some money on a special front sway bar.

-

Nice spreadsheet! Thanks

-

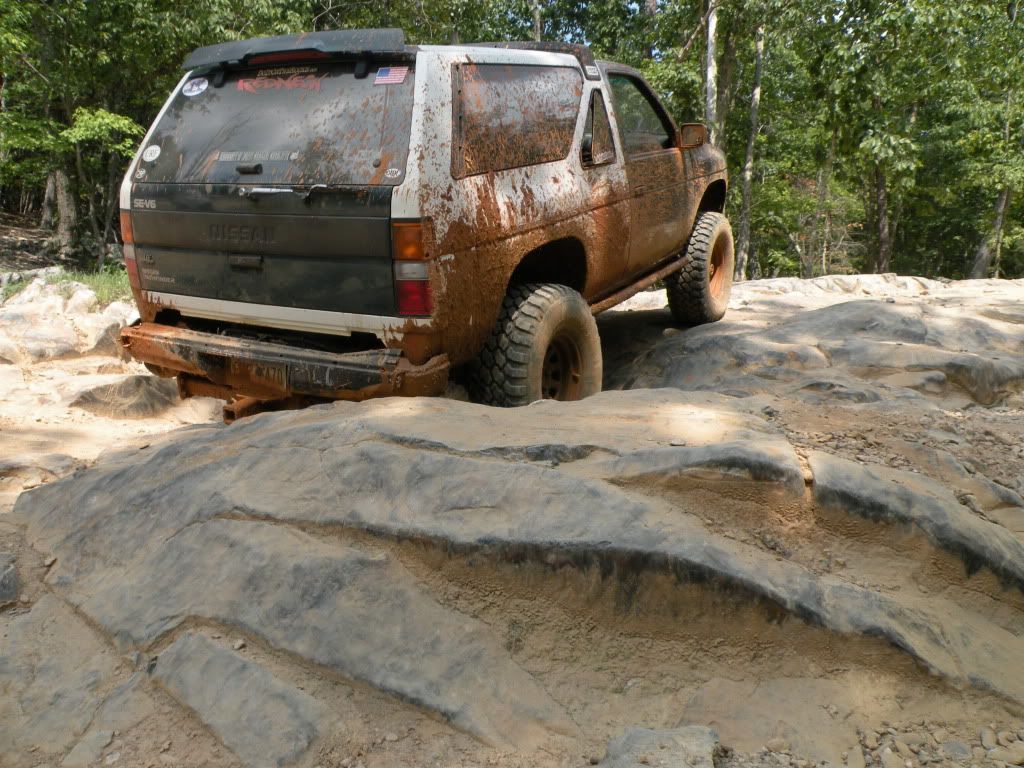

Some other abuse on it

Is that Uwharrie on Daniel? If so, those rocks got my bumper too!

-

Very informative guy's. Thanks. Cal mini no longer does 3.9 gear set or slip yoke eliminator . I have not been able to find another source. I have T-case apart now, to put automotive customizers gears in. I have tried to make SYE,but was not happy with results. I am getting tired of having pathy down , so probably going to put it back together and lenghthen stock driveline .

Hmm...Calmini still has the 3.9 gear set listed on their website. If I had to do it again i would have gone with their set because of easier install. Automotive customizers set is tricky tricky to get in since it reuses the original diameter bearing. Also, its larger gear requires more grind on the t-case oil channel if I remember correctly.

Anyway one comment, if possible have a second set of hands/eyes available at the final assembly stage with the AC gears. Getting everything lined up was a bear (at least for me).

J

-

Anyway.....I looked at the 94 tech manual to see the difference between the 2WD and 4WD steering connections. The idler arm of the 2WD is unbraced just like the 4WD. At a glance the tie rods and center link look less substantial then the 4wd ones. Before I swapped over to the 2WD system, I'd ask myself why did Nissan engineers make two different designs for 2WD vs 4WD....my first two thoughts are range of motion and strength. It would generally be expected that 4wd vehicle suspension will be put through greater range of motion and be subjected to more abuse.

The 2WD system may work adequately if you customize it completely to be strong enough to handle the abuse you intend to throw at it, but you may end up spending more money than if you bought something off the shelf such as the Calmini system. IMO, the Calmini system is geometrically the best design I have seen. I don't know about the quality of components they use or their material strengths. The Calmini system eliminates the twist on the center link by connecting the tie rods directly to the idler arm/pit man. I think the tie rods would still be a weak link due to the angle especially on lifted vehicles. However, TREs should be more inexpensive and easier to replace then the centerlink. Also, by extending the idler arm and pitman arm to allow the TRE to connect directly, there is an increased possibility of bending these under certain conditions. Hopefully, Calmini accounted for that in the material grade selection.

I'm not knocking the GR centerlink. It is definitely an improvement over the original, but is still subject to the twisting forces exerted by the tie rods due to the dog bone design. My friend installed a GR centerlink on his Frontier after the original started to fail during an offroad trip. It has held up well and shows no signs of degradation. I've been fortunate enough to not have failed my centerlink or bent my idler arm(which was braced at 150,000 miles). I have GR centerlink in the garage that I will install when the time comes since for myself I don't abuse my truck enough to justify the Calmini system. Got other toys I could spend that kind of scratch on ;-)

J

-

http://www.nissanpathfinders.net/forum/index.php?showtopic=5325

Found this....for newer models but steps should be similar

-

http://www.nissanpathfinders.net/forum/index.php?showtopic=17038

Have you tried this yet?

After market torsion bars are generally stiffer than OEM; therefore for each turn of the adjusting bolt you get more push so theoretically can get more lift. Keep in mind at some point you will need those other upper control arms so your tires can be correctly aligned.

If you raise the vehicles enough to get the wheels off the ground and look at the tires from the front they look like this \ /. Sitting on the pavement it should look something like this | |. Crank your T-bars and don't do alignment is like raising the vehicle so your tires starting looking like this \ /. With enough cranking there isn't enough adjustment with stock upper control arms to get back to | |, so you end up replacing upper control arms.

That is the best I can explain in a few paragraphs. There are other posts here abouts going into the details of lifting these vehicles.

-

1

1

-

-

2wd always.

Ok. that sounds like it might be a reasonable idea.

Is that realistically safe? On my bike, if I pedal the rear wheel, it creates centrigufal force that vibrates everything. That's not even going fast.

If I jack it up and get the wheels up to ~40mph, is it going to stay on the jack stands? Might it create insane vibrations and forces because the road isn't there to absorb them?

Well, I've done it myself without any issues. Remember, tires are high speed balanced so they shouldn't vibrate too bad unless you get crazy with it. Ideally you have a friend you trust run the gas pedal while you listen and watch. Have him/her bring it up slowly and if things start to make you uncomfortable tell him/her to let off and hit the brake. If things are stable and not shaking like heck then you can walk around the truck listening for your whine. Try different speeds and try listening when you let it coast down.

I always had the jack stands under the axle tube, so rested in the dimple/sunk area of the jack stand.

-

Could try jacking it up in the rear with both wheels off the ground and "drive" it to spin the wheel(s) it to see if you hear a similar sound coming from the rear without actually moving.

Obviously, safety first...solid jack stands under axle and front wheels chocked.

Are you in 2WD or 4WD when you hear the noise?

95 XE-V6 5spd Clutch issue (noise)

in General Forums

Posted

My opinion is the pilot bearing...which actually is a brass bushing. I had this happen on my 95 also. It usually was noiser in the winter/cooler months. Either way the tranny has to get pulled to fix it.