-

Posts

2,684 -

Joined

-

Last visited

-

Days Won

318

Content Type

Profiles

Forums

Calendar

Posts posted by hawairish

-

-

Drain and add new would be best. Don't forget LSD additive, unless you get gear oil that is approved for LSDs. Takes about 2.5 qts. I recently used this:

http://www.summitracing.com/parts/VLV-VV831.

Not sure about that switch.

-

hawairish, I understand what you are explaining. Thanks.

I am guessing that it is true that rubber bushings could hide this issue quite a bit because they might allow enough twisting at the 4 control arms to let the right end of the axle travel that purple arc. (and probably thereby shortening their lifespan a lot)

But dropping the PB bracket is definitely always the best thing to do (I installed my drop right off the bat).

Very likely. Especially worn rubber bushings. The poly bushings are more block-like, whereas the OE rubber has a decent gap between outer sleeve and control arms. That would allow several degrees of movement.

Hawairish, would a panhard drop bracket benefit a stock or modest (2-3 in) lift with articulation? Thanks.

It would, but it somewhat depends on lift method. Stock springs will obviously flex more than lift springs. Spacers and stock springs may be more flexible together than lift springs alone (for the same lift height), which means it'll probably be easier for the axle to overcome the pivot point gap and articulate better. The lift spring has to be compressed harder (aided by vehicle flex) to close that same gap. But in both cases, the drop bracket eliminates the need for either setup to compress.

As 96Pathfinder4x4 mentioned earlier: the drop should match the lift, but if you're not sure how much that really is, it's whatever length drop helps get the PHB level.

In my scenario, the weight of the chassis above the lift point was not enough to overcome the amount of lift gained from spacers and spring, so it just cantilevered the axle with it when lifting. I had to disconnect the PHB to make the right side droop, and when I did, I was immediately able to articulate at least another good 6" (mind you, I needed to completely unseat the rear spring to swap my spacers).

I had actually been meaning to have a bracket made before making this realization, but it kind of fell by the wayside. I really didn't think it'd be as pronounced as it was, though. I'll have to see if I can get a pic of me jacking it up off center...it didn't look right at all!

-

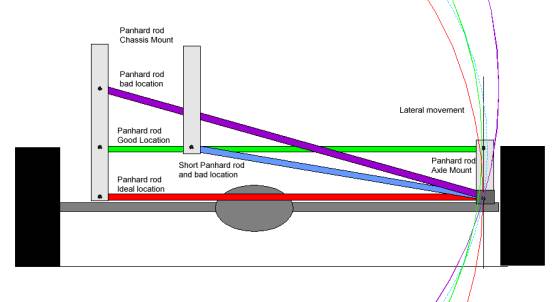

Here's a good pic to illustrate the point:

Ignore the green and blue rods. Those are for lowered vehicles or street cars, and are not good scenarios for us.

Purple represents our lifted setup.

Red represents the panhard drop bracket in place. You can see how the axle will effectively act like the panhard in this condition.

The aforementioned triangle is made by the the purple and red lines. Imagine each black dot as a pivot point, allowing the tire farthest from it to raise or lower. You'll see that pivoting on the left-purple's dot would require the entire triangle to pivot. But if it can't pivot (because the springs and 4-link won't allow it), then it cantilevers the right axle. Pivoting on the right-purple's dot does allow the left axle to droop, but the axle wants to shift left.

The red pivot points allow full droop on either side without the axle wanting to shift left or right.

EDIT:

And going full-circle as to why you're also not seeing flex up front, it's because your rear axle wants to stay flat, almost acting like a giant anti-sway bar for the entire vehicle.

-

1

1

-

-

I just ordered the krypton PB but I'm not sure it will drop the bracket low enough to be level with the axle. I don't ever recall seeing the PH being level. Maybe that's because I lifted it within a week or so of ownership. Right now with the WJ coils my rear sits really high! It will be about 3-4 weeks before I get the bracket.

Sent from my iPhone using Tapatalk

I hope it doesn't take that long. They told me 1-2 weeks, and I ordered a pair of them. I asked that they deliver before 8/14, and they said it shouldn't be a problem. Hopefully with 3 on backorder, they can make a batch.

But any drop well be far better than no drop.

-

On an old worn setup, it can be hard to get the drums off as the pads will have worn a channel inside the drum creating a lip. Hence hawairish mentioning the sledge hammer.

Not sure about our trucks, but most drum systems have a star adjuster to continually take up slack between the shoes and drum. You have a slot in the backing plate you can stick a 'spoon' or flat head screw driver in to and back off the adjuster to pull the shoes away from the drum and thereby let the drum pull off. But I'm never sure which way is looser and which is tighter...big pain sometimes.

But I have done a full drum rebuild, including all springs and miscellaneous parts without any prior experience. Key to my success was leaving one side intact to refer to as I put things back together on the other side.

There is a drum brake tool you might want to buy for a few bucks at the autoparts store that helps in mounting the springs. Not sure how easy that would be without the tool.

New drums about $50 each...steal has gotten expensive.

But the rest of the hardware is really inexpensive IMO.

And the bottle that hawairish described works out great. That way when pumping the pedal, air doesn't get drawn back in to the brakes. Just start with a little brake fluid in the bottom of the bottle, covering the end of the hose. The bleeder can stay open while the brakes are pumped a couple dozen times (with someone watching the level in the master cylinder to keep it from running dry).

Exactly the purpose of the hammer. But yes, there's a rubber plug on the back of the backing plate that provides access to the adjuster. But, it's a pain...you need one screwdriver to release the anti-reverse latch, and another to turn the screw. The FSM shows the direction to push the screw.

And leaving one side intact is a great approach, just remember everything is mirrored. The shoes are usually configured for LH/RH pairs, but if necessary, they can be swapped. In my case, when I pulled some good shoes off my donor axle, I had to take the parts that make them LH/RH off. Though I mixed up my adjusters and installed one on the wrong side at one point (doh). Since I needed to pull one shoe off each side of both my truck and donor axle, and then swap parts again (I had re-assembled both the truck and donor already), I ended up taking apart things 6 times. Ugh.

Pliers seemed to work best for me on the springs. Those twist caps probably more a challenge than anything...clamping the shoe to the plate freed up a hand to keep the spring pin in place.

Yep, I usually lift the bottle up and tuck it between something so there's fluid in the tube to prevent drawing air. And top off the master cylinder before bleeding and after a few pumps.

With your poly bushings, the lack of articulation could be from the triangulation that takes place between the upper and lower control arms. Probably has nothing to do with the Panhard bar. The PB allows unhindered travel in the direction of articulation, doesn't it?

Nope, it's the panhard. In addition to tracking the axle L/R, it's also the pivot for the axle.

At stock height, the axle tube should be at the same height of both panhard mounts, and the panhard level(ish). When you roll left (or right tire droops), the axle is pivoting on the left mount of the panhard; the panhard is then a radius arm (the axle is effectively the radius arm). When you roll right (left tire droop), the axle is pivoting on the right mount of the panhard on the axle; the axle is the radius arm.

With lift, you've moved the effective pivot point (an imaginary point on the axle) on the left side to a lower position, but the real pivot point is still the left hand panhard mount above it. In this condition, you've now separated the effective and real pivot points by a gap equal to your rear lift height. This is the triangulation (real left panhard mount, imaginary left axle pivot, real right panhard mount and axle pivot). In order to properly roll left (droop right), those two left points need to be compressed together to shorten the gap to make a single pivot point. A little gap is fine, because the rest of the suspension will allow for movement. Otherwise, you've created a cantilever.

The left side isn't as effected because the real pivot point on the right side of the axle still exists and is always the effective pivot. But what happens when you roll right (droop left) is that the axle must shift left to allow left droop (because the panhard bar is the radius arm). It wouldn't shift left if the panhard was already level.

My poly bushings are probably restricting left/right movement, but this is supposed to be a primary duty of the panhard.

I thought the panhard bar stopped the axle from moving side to side. Allows travel in angles, but not from side to side. Street rods will use adjustable ones. I assume that's when using different axles and tire widths.

The drop needs to be the same as the "lift".

For the reason above, it does both: prevents side-side movement, and allows for articulation.

The drop does need to be about the same as the lift, correct. At little less is fine because under most droop conditions, your truck is compressing on the other side because of the movement allowed by the suspension.

Also, the adjustable (or simply longer) panhards shouldn't be used to counter lift. It doesn't correct the triangulation, it just moves the axle to the right (or left, depending on which side the panhard is mounted to the chassis). You drop the panhard because it restores the proper pivot point.

Makes the sense?

-

1

1

-

-

Oooooh....I see now that the 01-02 alternator is apparently different from the 03-04, and it's only the latter range that is shared with all those other VQ cars I listed. I had only looked at the 04 parts thinking that it would've been unchanged throughout the years. Apparently not the case.

So, the belt I mentioned (and others) say they fit 01-04. That means either the alternator bracket is different, or the pulley size is slightly different (and should be negligible because the alternator can be tensioned by the bracket). The pulley grooves must be identical. If the brackets are different, I wouldn't be surprised if they could be swapped. If you want to get some pics or measurements of yours and compare them against mine, let me know.

Hard to say about reliability. By the looks of it, the seller for the two alts I saw sells only alternators and starters, and most of the alternators all appear to be high output. All "new" and "upgraded". And seller has positive feedback. I'd like to think those are pretty good signs. Says there's a warranty, but no details.

-

Yeah, the panhard angle matters. It should be flat because a larger angle will essentially triangulate things in a bad way. A small angle isn't terrible, but not efficient either. The strange thing on mine is that my axle appears to sit perfectly centered, whereas I expect it to be more on the driver's side. Must be the SuperPro bushings.

My "tool" to bleed brakes is a small box wrench, another person's foot, a short length of clear vinyl tubing, a plastic water bottle, and two cable ties. The tubing, bottle, and cable ties make a catch bottle: drill a hole in the cap, put some tube through the hole, cable tie the tube on each side of the cap to keep the tube from coming out, then twist the cap on the bottle. The vinyl tube ID should be small enough to fit snugly on the bleeder valve's head.

Other tools to complete the job: flat screwdriver, channel pliers, quick clamps, a mini-sledge hammer. Not what you were expecting, eh? The latter two are optional, but can come in handy.

The wheel cylinder is a dual-headed piston assembly that pushes the tops of the shoes apart and towards the drum wall to apply braking force. The brake line and bleeder valve attach to it. If loosening either causes any damage or snaps off, it'll be the wheel cylinder that needs to be replaced. It just bolts to the backing plate.

Changing drums—or brakes for that matter—is one of those things where if you see it once, and you're a pro (sort of). If you're really interested, I'll write something up and toss it in the How-To, assuming there isn't one already there. The toughest part of the job for me is getting my wife to tell me when the pedal feels firm and when it hits the floor when we're bleeding things.

-

Just checked an alternator belt, Dayco 5060463...shows as fitting a 04 Pathy and 350Z. Do it!

-

Thought so, but why look into the Maxima or Altima belt? The 350Z ones should just drop in.

eBay has a 180A for $170 and a 240A for $276, shipped.

-

I have had too many of those types of electronics (T-max) fail on me. The buttons get old and crack/corrode and its just not worth it for me either. Thats great info on the Blue Sea switch, sounds pretty capable! I think that is the direction id like to go as well (as if i need another project right now...lol).

If you dont mind me asking, where do you source that kind of plastic from? It seems like there would be tons of uses for something like that.

Overall, sounds like a good plan! Im looking forward to seeing the install (if you decide to post it up). I would tackle this one soon... But i think it would work better with an engine in the truck... Lol. (Partway through an unnecessarily lengthy vg33 swap). But i hope to see yours soon!

Yeah, I'm not sure how well the label on the meter will hold up in the heat tucked away in a glovebox. Surely the heat can't be good for it.

Tappplastics.com. I've use them for a couple years for various computer projects and materials. They do custom cuts to precise sizes, or you can buy standard sizes/pieces. All sorts of neat materials. I've also found that if you decide you want a specific size cut (especially small sizes), that you can get multiple pieces for the same price as 1 piece. So I just have them make as many as I can get for that price. Maybe if I need a custom size, I'll pick up extras and send a drilled-out one your way since it sounds like we'll use the same components.

The ABS is particularly nice because it can be tapped easily, and resists cracking (especially where drilled), and can be heat molded. http://www.tapplastics.com/product/plastics/cut_to_size_plastic/abs_sheets/524. I have some leftover sheets for a project I did on my Jeep...mounted a small power inverter, small OE sub amp, and fused power block to a sheet mounted to the rails of the passenger seat...having it move with the seat saved it from being stepped on by people climbing into the back if I had mounted it to the floor. But because it's plastic, also makes for a great electrical insulator.

They also sell HDPE sheets (the stuff Fleurys uses for spacers), and various acrylic sheets.

I bumped this project to my "on deck" circle, once I'm done with this tire carrier retrofit. Thinking I might be drilling some mounting holes for it tomorrow... Thinking this project might come alive in a month or two.

-

Wait...don't you have the VQ?

-

Stock alternator is 110A.

Several sites (including Rock Auto), say OE alternator fits any VQ35 engine: 350Z, G35, FX35, M35. The original alternator p/n 23100-AM610 was superseded to 23100-AM61A...but if you eBay search the old number, it returns results for multiple vehicles. That said, there are 220A-350A+ for the 350Z...and thus, the R50.

(And as an extra cross-ref, as I'm prone to do, the R50 pulley p/n is 23150-AG010...which if you Google, returns results for the above vehicles.). I'd say you have direct fit options that don't require a belt change.

(And as an extra cross-ref, as I'm prone to do, the R50 pulley p/n is 23150-AG010...which if you Google, returns results for the above vehicles.). I'd say you have direct fit options that don't require a belt change. -

Thanks for the info. Believe it or not, both my 97 maxima and my pathfinder have had corroding aluminum rims. Likely it's not something you have to deal with because you have a warmer climate.

I have seen many alloy wheels corrode badly, most likely starts as damage to the clear coat, then the salt gets underneath it and the pitting begins. So if there were scratches close to the bead area from tire weights, mounting or curb rash there would be no stopping it.

I don't doubt they corrode, and I've lived in salt states for a few years (MN, IL) to know the impact. But, for something that took many years to occur on aluminum, I don't see how steelies would fair any better. Powder coating will succumb to the same fate of clear coat, but the steel will rust a helluva lot faster. I know because I had steelies on my Frontier; they chipped, and immediately rusted in those spots...even here in the high desert.

But anyway, I didn't want my takeaway from my post to be about aluminum vs. steel vs. corrosion. Hope you find the info useful.

-

Welcome to the forum!

I'll be the bad guy before the admins, moderators, and just about everyone else chimes to say you're off to a really bad start:

- Don't cross post...people don't want to see the same message in multiple locations. Your first 3 posts were the same and in two different locations.

- Search...it's very clear you haven't done any homework...

- See pinned articles...these are pinned for a reason: because a lot of people ask about them. There are some that specifically address lifts, components, where to buy them, how to install them, and pros/cons.

Seven of the first 10 results for a ridiculously simple Google search for "Nissan Pathfinder lift" returns two popular sources for Pathfinder accessories (including lifts); two eBay results for lift spacers sold by guys on this forum; a YouTube video of a 6" lifted Pathfinder (also from a guy who used to be on this forum) running something called a SubFrame Drop (SFD) lift; and a Suspensions Lift 101 thread at the NiCO Club forum specifically for Pathfinders and QX4s. The other three links have generic parts that probably don't fit anything Pathfinder. Then, within results 11-15, two are for another popular source for Nissan trucks/SUVs (the owner frequents this forum), and the 15th result is the vendor who produces the aforementioned SFD, which is a 4" lift kit.

Don't let me spoil things, though. You'll find a TON of really good information and people on this forum compared to the others out there. But you'll get much better answers if you have a specific question about something.

-

2

2

-

Meh, rear brakes are a piece of cake! If the bleeders are rusted out, might as well replace the wheel cylinders while you're at it...$10/ea US on Rock Auto. Easy to change when doing the pads, and it's the perfect time to do it. I could even make you a how-to video (er, write up). (Donor axle in garage with used genuine Nissan Akebono cylinders, if you want 'em!).

Did you get the panhard drop bracket? If not, that might be why. Without it, your the right side of your axle can't articulate, and the truck will resist body roll.

I realized my truck is having that problem when I went swap my rear spacers over the weekend. At one point, I could put the jack on the axle under the left spring, and the axle would basically raise evenly. I had to disconnect the panhard bar to remove the right spring, then had to use a ratchet strap to reconnect it. I ordered one up the other night...but looks like it might be a couple weeks before I get it.

-

Xterra wheels like Pathfinder wheels will come in different sizes. AFAIK the bolt pattern on all or most Nissan's is the same, especially on these 2 vehicles (6x5.5).

Actually, most Nissan truck/SUV wheels before 2005 will fit to some degree. 05+ will not fit because they are 6x4.5. You could get adapters, but the center bore would be too small if you have hubs (4wd)

Titan/Armada wheels have the right bolt pattern, but the center bore is too small for 4wd Pathfinders. For 2wd, you can usually groove a lip on the wheel mounting side to clear the ring on the hub (100mm). Not sure if there's enough metal to make them fit 4wd, but I don't see how there couldn't be.

Some Xterra/Frontier wheels are 15". Older R50s came with 15", but the facelift ones came with 16" and 17". The 15" should fit as long as the calipers didn't change (don't think so). The backspacing and offset varies.

-

Please keep in mind I'm a poor Western Canadian boy and can't get stuff shipped for $.99 like you lucky Americans.

Nah, we get everything shipped for free.

Not to take away from getting steelies, but I'm curious why you're having seal leaks in the first place. A bad seal is a product of bent/damaged wheels, a bad bead on the tire, or even bad bead sealer. A slow leak is a tire issue 99% of the time. And I would imagine the aluminum alloy used to be rather resistant to road salts. Just food for thought.

Your understanding about +/- offset and backspacing is on the right track. Except a smaller backspacing on the same width rim moves the tire out away from the wheel hub. Backspacing is relative to the wheel width; offset is resultant of both. The rim width, offset, and backspacing are all correlated; you can basically determine any one if you have the other two. Offset is probably the one I'd think about less when making a decision on which to get.

You can see that backspacing is the distance from the mounting surface of the wheel to the edge of the wheel. Offset is the distance from the mounting surface of the wheel to the theoretical center of the wheel; + offsets are outside of the center, - offsets are inside. Specified wheel widths are generally 1" wider physically, so for 4" of backspacing:

- a 6" wheel (physically 7") has +.5" offset (or 12.7mm or 13mm)

- a 7" wheel (physically 8") has 0 offset

- an 8" wheel (physically 9") has -.5" offset

If you are going from a 7" wide wheel to an 8" wide, and keep the same offset, your backspacing will increase and come closer your strut. Since you need the wheel to go away from your strut (or stay the same distance away), you need to decrease backspacing. If you want to get an idea of where your stocks are, just measure them like shown in the pics. Then, eyeball down the side of your truck and think about how much farther out you'd like to have the tire, then go from there. This is a personal preference.

Also, if you plan to go beyond the 254/75/16, consider a 16x8. Most taller tires I've seen have an approved rim width of >7.5. I don't think many tire shops will flinch when mounting to a 16x7, but who knows what "approved" will really mean if something fails.

-

I don't see where you got the hitch.

Does the tire swing down so you can access the rear? ...or to the side?

It installs in his hitch and swings to the side, but has a pass-through receiver currently occupied by one of these:

-

1

1

-

-

Agree on the jerryrigging. My best so far was using hinges and random bolts to make my steering wheel puller into a crankshaft pulley puller.

Let me tell you about the 2x4 I used to for holding R200 diffs for torquing on a vice, keeping an axle stationary so I could test LSDs break-away torques, as a torque extension on said axle, and most recently to un-bend a bracket for a tire carrier mount...

But not to get too far off topic...

-

1

1

-

-

Yep, seen it. It just talked about battery and mounting options, which I have no concerns over. I plan to buy a pair of plastic battery trays in the sizes I need, rivet them side-by-side, and fasten to the chassis. Ones like this have integrated straps...no point in re-inventing the wheel.

Seen the Theexbrit's setup, too...same as 96Pathfinder4x4. Both use the T-Max and have a RigRunner for accessories.

-

Yes, i think that would cover the necessities, other than adding your own voltage readouts, which i think you said you already have (at least for your current setup). I like the idea of the blue sea systems rotary knob vs tmax's style of buttons from a durability standpoint. Also, a quality electrical component designed for marine environments should be ideal for our purposes due to superior corrosion resistance, i would think. What do you think about vibration? Would that be more of a concern for 4wd than it would be for marine? Maybe that answer would depend more on what type of wheeling one does with their rig... Also is dust a concern? Im still vacuuming dust out of my pathfinder and i havent wheeled in the desert for over a year! Lol. (Used to live in SoCal)

Are you planning to put them both under the hood?

I prefer a physical switch, too. There are a couple other little nuances about the T-Max that have me hung up...one, it doesn't appear that there's any integrated way to mount it (I'm not using Velcro, and it's not going to get tucked away somewhere), and two, if the Link button should fail for any reason (integrated circuit, melted tactical button), I'd have to cut wires to bypass it (which I don't want to do). I'm a big stickler for clean installs.

The Blue Sea modules are IP66 and IP67 rated, meaning they're both dust proof (the first "6") and resist either powerful jets of water (the second "6") or full immersion (the "7") for a minimum period of time. And of course the superior corrosion. If it can withstand of the neck-jarring impacts of a boat going through crests at speed, I have no doubt it'll withstand vibrations from on/off-road. Even then, it would be pretty easy to put those units on rubber feet, but probably not necessary.

I'd mount them under the hood, probably somewhere near the passenger strut tower or firewall. I tend to use ABS plastic sheets (1/4") for mounting things...rigid, insulating, easy to work with. I think it'd be pretty easy to make a one-piece module that holds a switch, ACR, and pair of breakers.

-

I think I see what you're saying...since the smaller battery would only be for starting, it probably doesn't need to be on the alternator-side of the isolator or ACR.

But, the more I think about it, though the less I think it really matters as long as:

1. The batteries charge together

2. The batteries discharge separately

3. Whatever electronics to be used for prolonged periods between starts are connected to the deep(er) cycle battery.

I probably will plan for a setup with a deep cycle when the current battery croaks. This power project will eventually support an inverter, air compressor, water pump (for an onboard water supply), and maybe even a fridge. But I also want the radio and cabin lights on that circuit, and redundancy for starting. I think that Blue Sea kit is the "essential" items.

...but if I'm not mistaken, all that's really essential is an isolator, which is just a big relay: + from battery 1 to one side, + from battery 2 to the other side, and a latching signal across two other terminals (12V when the ignition is ON to ground). A selector switch is useful for selecting which battery(ies) to use for a function (like starting), or combing the two for jump starting. The T-Max is useful if you want meter readings, and both the T-Max and ACRs manage the charge (when both batteries are charged, it opens the circuit to prevent over-charging, then senses when the secondary battery has discharged enough and closes the circuit...kind of like a trickle charger).

Is that it in a nutshell?

-

Are you currently running a deep cycle battery? That would be the best choice for frequent current drain applications with the engine off, as far as i know... Something like this:

Im planning on this being the second battery and then getting another to be the main battery when my current standard die hard, dies...

I'm not currently running a deep cycle, but I think it's on its last leg anyway. The heat and age has been taking its toll and if it sits for a couple days, it takes a little extra to turn over. I was thinking something small for the starting system, maybe a Group 25 size, and then a basic battery. I don't currently have anything that warrants an Optima, but eventually I will.

-

Look up ThExbrit. He has a dual battery setup. Also on Expeditionportal.com there are a ton of dual setups.

Sent from fat fingers on S6

Yep, I read Theexbrit's, 96Pathfinder4x4's, KiwiPete's, and some info from XPLORx4 and his components (not sure about his setup) and a few other outside of here including one particular gem on ExPo before posting. I've seen numerous diagrams, and have read up on several configs, including some provided by Blue Sea and other marine applications.

But none really answer my questions, just explain the typical setup of just adding a battery, and adding new stuff to that battery. The one question in particular interest is divorcing the starting system from the other electronics (how easy, and if worthwhile). The few diagrams I've seen just show the starter/alternator on battery 1, and everything else on battery 2...but it's not clear to me how everything is just simply separated like that.

Servicing LSD rear end

in 90-95 WD21 Pathfinders

Posted

Drain and add new would be best. Don't forget LSD additive, unless you get gear oil that is approved for LSDs. Takes about 2.5 qts. I recently used this:

http://www.summitracing.com/parts/VLV-VV831.

Not sure about that switch.