Balln

-

Posts

183 -

Joined

-

Last visited

Content Type

Profiles

Forums

Calendar

Posts posted by Balln

-

-

Ok cool thanks guys

-

Hey guys quick question I keep reading how everyone takes the oil filter off to swap the starter. I have a free oil change at my local Nissan and would like to swap my starter before i take it to them. Or can I take my oil filter off with out it completely draining and swap new starter then take it to Nissan?

-

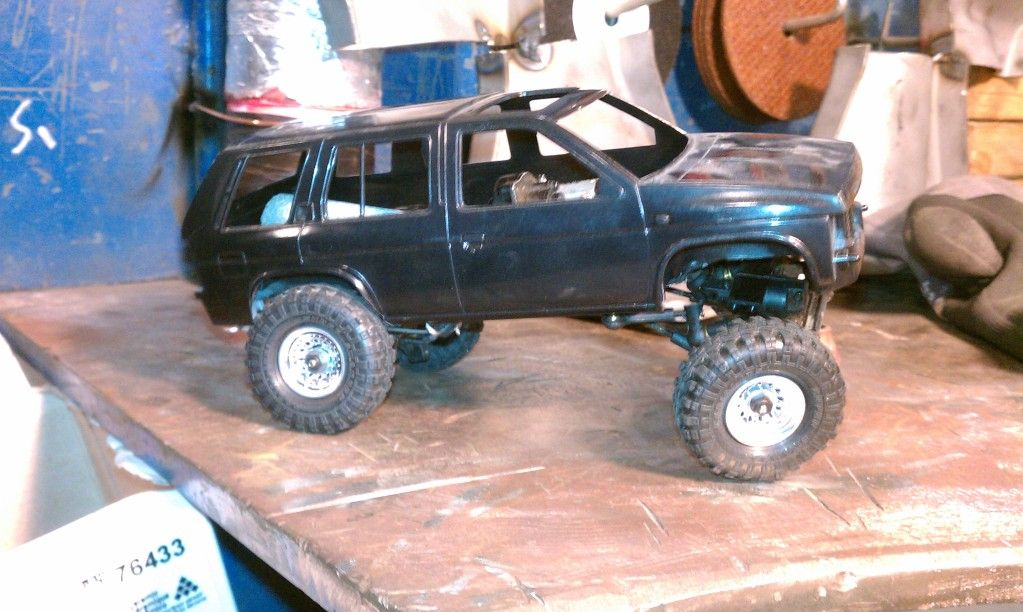

Thanks guys. It gets more flex its just really light right now. I wanna keep it looking close as posible to my pathy but once I get all the electonics and scale goodies on it ill see how it performs and if it needs more weight up front I may build some arb bumpers instead of wheel weights.

-

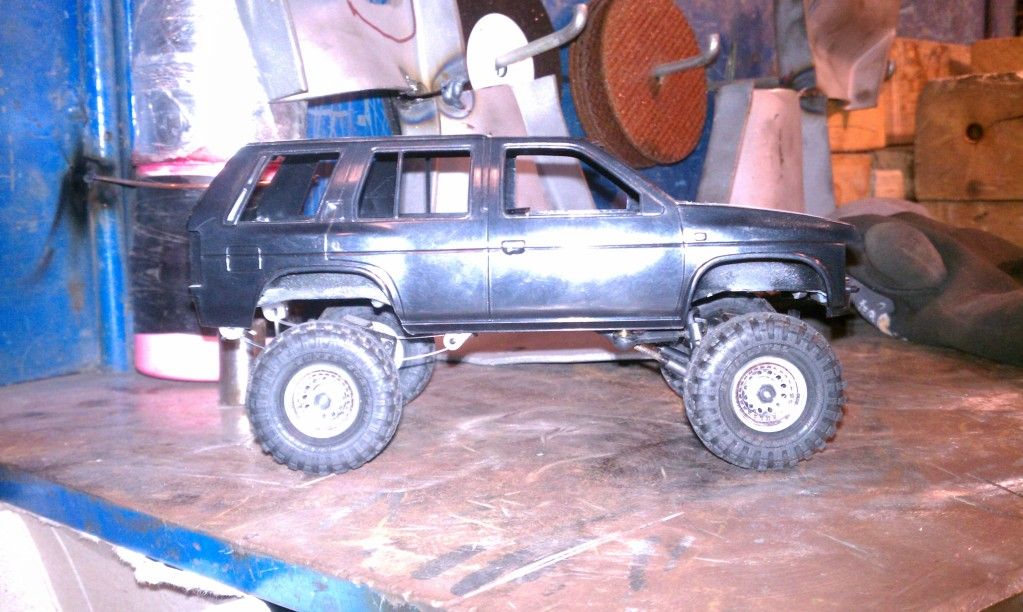

Starting to come together i also got the steering servo mounted just have to make the steering linkages.

-

1

1

-

-

OK guys its been awhile since i have posted any updates. I couldnt figure out how to mount the front axle so i put it in my tool box at work at thats where it sat till the other day i decided to take a look at it and it hit me i figured out how to mount it lol. Here is some pics

More pics coming, waiting on Photobucket

-

Man,Balln that is one sweet 94. wellcome to the club.Good Luck and enjoy.ps tires are fantastic! jack

Thanks man i love my pathy. Next step is to get my exhuast done, sound system, Trans cooler mounted, susp lift, Mount my jerry can and highlift jack and so on and so on lol

I figured i would post these pics up. NOTE!!!!! MAKE SURE YOUR MOUNTS ARE NOT BENT IN ANY WAY AND TO GET A STRAIGHT CUT!!!!!!!!!

I had some extra front bumper mounts laying around and grabbed them on my way to work to cut and weld them (factory ones where still connected to the bumper). Well not really looking at them that good i made my marks and cut then tacked them together. After getting home the next day and mocked them up is when i relised my cuts where not straight up and down like they should be.Come to find out my passenger side mount was in a fender bender. with the way i cut them when i moved the front half up 3" it moved up and back which made the bumper not line up at all. So after i found the right spot i put in my gusset and fully welded it up.

After the bumper was mounted i then had to clean all the mud off and out from under it. THAT SUCKED and was not worth the couple mins of me getting to play around in the mud.

-

The starter? Flywheel?

-

Hey guys i have read and searched but couldnt find anything that really helped me out. I have a 94 pathy v6 4x4 auto tranny 150,000. My question and problem is every now and then when i go to start my pathy the starter sounds like it doesnt engage all the way. Its a real load noise (grinding) and embarassing. When it happens i just stop and then retry it again and it usually starts up it has done it a second time in a row but then starts up on the 3rd crank. Im wondering is my starter going bad? Maybe alot of crud inside of it? Im guessing its the factory starter with 150, miles. Is the soleniod going out or getting bad? Or my worse fear is, Is my fly wheel fudged up? Everytime it does it is the starter engageing in a spot where there is no teeth on my fly wheel? Im thinking too if there isnt any teeth for it to grab and is making that noise then how does it usually crank up after it happens. It would have to grab the bad teeth good enuff to turn it to get ahold of good teeth but then it would have started? Idk My brain hurts from thinking about it.

Please help me out on this.

Thanks Guys Ryan

-

I finally installed my body lift and wow what a job that was by my self but i got it done. I had some speed bumps like the one bolt that didnt want to come out of the front bumper mount so i cut it off then i was able to get the whole bolt out. Then i went on a wild chase for rad hoses. The top was easy but the bottom was crazy. I ended up using the stock one after trying to see how it fit. I was able to slide it up ferther and it didnt kink. Go figure. I still have to figure out my front bumper mounts and raising the rear up. I went for a test drive and found some mud wholes. Ill try getting some pics of it all cleaned up and with the bumpers done.

-

The way i would build tube arms i would have to make jigs and really dont want to lol. I have it in my head to modify stock stuff and im just kinda going with it lol. I dont plan on paying the prices from a JY. There are a couple pathys being parted out by private sellers hopfully i can pick some up for cheap.

-

Yeah thats what i was planning on doing getting them from a yard. And yeah that was another concern with the bump stop area. Well i got alot of my concerns answered and i guess its time to get some and just cut them up. I can always recess the bump stop sectin into the arm a bit. i guess i can just play with them and see what i come up with.

Thanks agian guys i plan on updating this thread with what i find out.

-

and BTW this thread is 5 years dead.

LOL

-

Ok cool that makes since. And if i where to angle them they would be angled up more. As you crank the T-bars for more lift the upper arm goes down and the balljoint end goes down cuasing the joint to bind so i would need to angle it up and that would push the ball joint out away from the frame. With that said i would more then likly have to push the arms in towards the frame cuasing it to maybe take shims out rather then installing them. Correct? I guess ill be the ginny pig and try it lol

-

you are correct the tubular arms are designed to give lift without the ball joint spacer, you may be able to re-work the stock arms and still get the truck aligned with the stock bolts.

ok And when you get aftermarket arms do they give you longer bolts or you use the stock ones? If you use the stock ones then i shouldnt have any issues with angled stock arms seeing how not of that changes.

-

My hardbody never needed longer bolts to align it, and it didn't have a bunch of shims between the arm and the frame either.

The purpose of the ball joint spacer in the modified arms is to allow you to crank in more lift before the arm makes contact with the bump stop.

The tubular arms has nothing to do with "extreme cases" as you say, the purpose of the tubular arms was to eliminate the ball joint spacer as the tubular arm is angled to allow more lift to be cranked in than if you were using the stock arms.

Im starting to get confused weather i even need angled arms are not? lol And i was looking at my arms today and it seems like there is already a spacer between my balljoint and upper arm? not sure if thats stock or not? So i can either run stock arms with no mods what so ever and bolt on a set of spacers and i will not have any issues getting it alighned? Or just buy some stock arms angle them up a bit and weld them up and have no issues with an alighnment?

The junk yards want from $50-100 for both stock upper arms and balljoint spacers are $100 shipped.

Thanks guys for helping me out im just trying to figure out the cheapist way to lift my pathy but not half ass it. I could go out there now and take the bump stops out and crank the @!*% out of my T-bars and let it roll but i dont wanna do that.

-

The stock arms allow plenty of room for alignment with bigger tires but it's only the bolts that attach them are too short from factory. You need longer bolts to be able to stack more shims for camber correction. Ball-joint spacers are a plus but you most likely will not need them. Only in the most extreme cases would you even need aftermarket tubular arms. You can tweak the tubular arms if you wanted to for whatever reason without issues since they should be heavy duty. There should be no need to do that though.

The whole reason i plan on going this route is to ditch the price tag on aftermarket arms and lifting my pathy. So if i where to buy them i would not modify them. I wanna use stock ones becuase they are cheapier and i can build them my way and box them in and all that good stuff to make them different from all the others out there. And correct me if im wrong but the only difference between stock arms and aftermarket arms other then looks is that the end (where the ball joint mounts) is angled more? If so then i would still have to get longer bolts to be able to stack more shims for camber correction. I never heard any of the guys that have aftermarket arms running into this problem but i can be wrong?

-

nothing wrong with that

Personally I am against modifying factory one piece components such as center links and arms. You completely compromise their structural integrity. You can get aftermarket tubular arms and play with those instead.

The original aftermarket UCA's were stock arms with a ball joint spacer welded in and the bottom of the arm fully boxed, no they don't correct the angle but that's how they were before the tubular ones became available.

If he bought aftermarket tubular arms, what the hell would he need to play with? They would already have the angle built in he was trying to achieve.

nothing wrong with that

Yeah I really don't see either

Personally I am against modifying factory one piece components such as center links and arms. You completely compromise their structural integrity. You can get aftermarket tubular arms and play with those instead.

Well I'm with you on cutting stock stuff up but I will be beefing it up more then stock. I Tig weld on big ass turbine parts and my welds are good enuff for them to generate power to run cities then they should be.good enuff for some A-arms. Lol. But the whole idea is to save $ I think those arms are to pricey for what they are and do. And I understand if they break then I will be spending a lot of $ in repairs but I really don't see them breaking.

The original aftermarket UCA's were stock arms with a ball joint spacer welded in and the bottom of the arm fully boxed, no they don't correct the angle but that's how they were before the tubular ones became available.

Hmmm didn't know that but I've heard not to run those balljoint spacers and the stock arms with cranked T-bars make it impossible to get a tire alignment done. So I'm really wanting to have some angled arms.

If he bought aftermarket tubular arms, what the hell would he need to play with? They would already have the angle built in he was trying to achieve.

Lol in a nicer way yes what he said.

I have seen some shady @!*% done to some bagged mini trucks that are still holding up. I have a friend that bought a bagged truck and the 4-link tabs where only welded on the outsides. The truck started swaying back and forth and I told him to let me the #&*% out. He still drives it daily like that and its still running strong lol.

What do you guys think the going price would be for some stock upper arms? And I'm thinking the best and easiest way to get the angle is if someone who has some aftermarket arms can make a templete with cardboard of the angle and ill pay to mail it to me?

-

Hey guys I was wondering if it would be possible to pie cut the bottom of my upper arms and bend them then weld in inserts to gain the better ball joint angle? I would add more material and beef it up just for my piece of mind. We have done it in the past with mini trucks and the balljoint binding. Just pie cut right behind the balljoint lay the truck out then make inserts and weld them in. I have the access to material and a Tig welder at work and the only cost would be getting the arms from the JY.

What's your guys thoughts on it and can anyone supply me with how much the aftermarket bent arms are bent more then factory?

I know I could make a jig and build full custom arms but I really don't want to spend all the time that , that project would take. I'm hoping I can wam bam thank you mam these arms at work in one day.

Thoughts?

Thanks guys

-

I have a SE with the power shocks. If i do the JGC springs and crank my T-bars will my stock shocks be good? Will they be long enuff? My shocks still work and i like having the option of switching them to sport mode but i never use it. So i guess aftermarket shocks wouldnt hurt but just wondering if i could get by, by running them?

-

Im going to install my oil pressure guage tomorrow and was wondering about how to wire up the light. What im wanting to know is it ok if i run a jumper wire off one of the wires from my light dimmer switch? That way it can be adjusted or should i find another wire behind the dash? and if i do will it mess anything up? I just dont want to FUBAR my truck up with such a simple little light bulb.

Thanks Guys

-

Congrats man!!!!

-

Hell yeah def post some pics up!!!!!

-

I have titans on my hardbody and bored them at work with a friend. I seen where a guy put some on his 4x4 hardbody and it looked like he took a lot more off to me.

-

You have to bore too much material out on the rim to make them to fit the 4x4 hub and is very unsafe to me. They would look good on a pathy but not safe.

starter swap without removing the oil filter?

in 90-95 WD21 Pathfinders

Posted

Yeah mine is a 94 auto with a body lift hehehe forgot to mention that part. So I should be able to squeeze it out between the bottom of the wheel well and top of frame?