- Sign In Changes: You now need to sign in using the email address associated with your account, combined with your current password. Using your display name and password is no longer supported.

- If you are currently trying to register, are not receiving the validation email, and are using an Outlook, Hotmail or Yahoo domain email address, please change your email address to something other than those (or temporary email providers). These domains are known to have problems delivering emails from the community.

-

Posts

137 -

Joined

-

Last visited

-

Days Won

8

Content Type

Profiles

Forums

Calendar

Everything posted by peejay

-

Well, the heat gun in "stock" form didn't work. Have since ordered the cone accessories to better concentrate/direct the heat, coupled with the Kroil that also arrived. (Currently using a wood block to keep the heat away from the wiper reservoir area). Have been trying with the ratchet strap, (not using the ratchet feature), just my "brute strength" to yank on it, the m/c will move SLIGHTLY, but really only from the top stud, towards the left front tire, can't get it to move towards the right front tire at all. If the heat won't get it, and dremel contraption is gonna be cumbersome, gonna protect/give some clearance to the stud threads (rubber hose, old credit card, etc) and try and chisel the ear and bend whatever gap I can make. Will try and post pics when I hit pay dirt! (Oh, thanks for chiming in, Slart, you helped me make sense of the EGR solenoid circuit many moons ago!)

-

Have you tried car-part dot com? Looks like they have one from a '92 XE MT 4x2, maybe you could swap the good bits if need be?

-

I may try the heat gun! I have a bernzomatic torch/MAPP, but i'm VERY nervous about using it in that confined area (paint on the firewall, discoloring/ harming the stud, anything that may burn/melt on the inside...I've been "burned" once before with that torch on an ATV carb, when patience and penetrant alone probably would've sufficed). The kroil and cold chisel should be here today... Got some cutoff discs, just using that as a last resort... (Toying around with a rotary tool/flex shaft, but even that may be tight). I may need to yank the washer reservoir first (and possibly the brake booster) to get max working room...

-

NOW I'm on the trolley! Getting the m/c to rotate around the lower stud sounds like the way, it's just going to take me ALOT of gulp, patience to get there. (Forgot to add the disclaimer that this is near the extreme end of shade tree...no air compressor, no AC outlet...so hand tools and at most a cordless rotary tool...wish me luck!) Thanks, will post my "progress"!

-

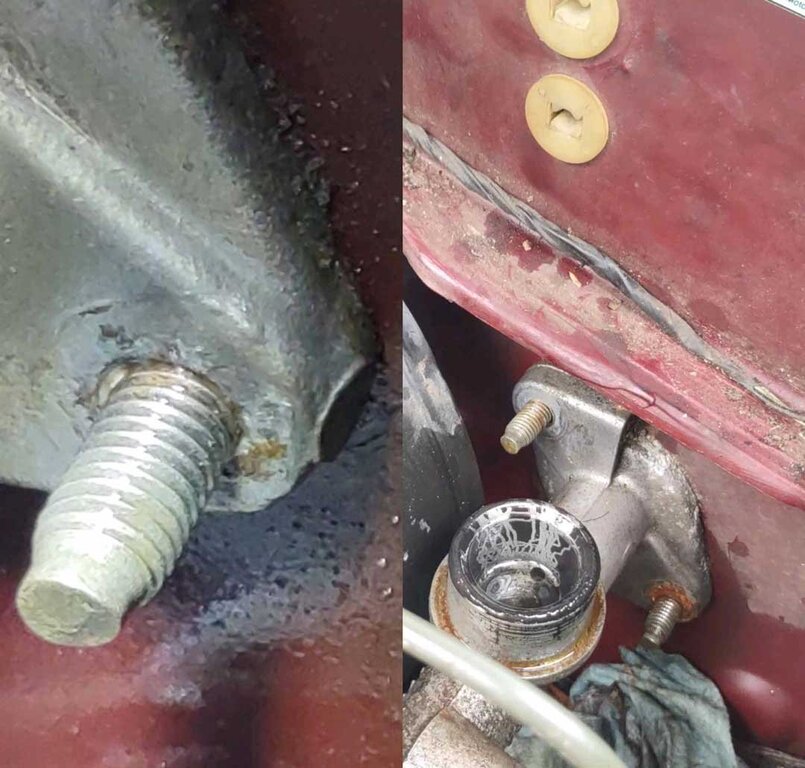

Thanks for the tips! I wanted to avoid (if possible) hammering from the top or bottom to reduce the likelihood of deforming the studs. You can't see any "daylight" around the threads of that lower stud, telling me that the threads are fused with the master cylinder. I'm leaning towards carefully use of a cold chisel in the area, maybe a slit in the 3 o'clock position, enough to wedge a screwdriver or something in to free the m/c from the stud.

-

Okay all, getting that "no, don't do THAT!!!” feeling, how in the heck do I remove this clutch m/c, it appears it has fused onto the lower stud? Tried beating on it from the inside (rubber mallet, long wooden dowel), no dice. Tried wire brushing and pb blaster, nope. Got some better brushes and kroil on order, trying to avoid heat (MAPP gas) and a cold chisel, if possible. Also, when/if I DO manage to get it free, is the m/c going to "easily" clear the brake booster? Thanks!

-

Thanks, RCWD21, I seem to recall reading that somewhere. Guess with a 5-gal reserve there's no excuse for running out-of-gas!

-

(1994 Pathfinder, V6) I apologize if this was posted before, I searched (briefly!) but couldn't find it... Trying to determine if I have a 15 or 21-gal tank, without having to run the thing empty! The fuel gauge is reading incorrectly... Let's 'assume' I'm getting 16mpg 'conservative' city driving... I reset the trip odometer the last time I filled up... Say I make it to the gas station with 240.0 miles showing...(and 16mpg x 15.0 gal = 240.0!) If it takes around 15-gallons to fill up the tank, do I have a 15-gallon tank? (That's what happened the last time, I don't think I've EVER come close to putting 21-gallons in this vehicle).

-

Slarti! How's it going? EGR valve/circuit is still working like a champ! You were able to section and weld your frame, no? Still lookin good as new?

-

Thanks, PathyAndTheJets! Sounds like a straighforward plan to follow! When/if I get a better frame, I'll post pics to document the procedure!

-

Thinking of getting a frame from the junkyard to replace mine that's got the rear frame rot. Are there things I can do to the "new" frame to keep it from suffering the same fate as the old one? Thanks!

-

Great suggeston, precise! I like the idea of the title containing the location/items! And of course, the threads could be deleted after a set time, and reposted if the vehicles are still on the lot!

-

Hi, all, what say you (and moderators) to a forum/sticky for vehicles we find in salvage yards, to help in our seach for hard-to-find parts? we can give the name of the yard(s) in a PM so as not to be freely advertising for these businesses? for example, i found these two in a yard near me (PM for info), the '90 maroon/gold one has the disc brake rear end with posi trac (i spun one side, the other side turned in the same directions), and the green '94 has all the lego wheels (as of today). IMAG0558 by Tamiya Striker, on Flickr IMAG0562 by Tamiya Striker, on Flickr IMAG0567 by Tamiya Striker, on Flickr IMAG0568 by Tamiya Striker, on Flickr

-

Thanks for the replies! I'd like to steer away from running it to empty, reading about fuel pump failure and what not...and the fuel pump gets VERY noisy right now when the gauge gets on E... Also, maybe the previous owner had the tank replaced before I got the truck? I will try and measure it as best I can in-vehicle...if it turns out to be a 15-gal, and i find a 20-gal, i will try to take and post side-by-side pictures of both tanks! Oh, right now I get aboug 240 miles on a full tank, and that's mostly city driving, no more than 60mph on the highways...

-

Ahem, that's "Precisely" the information I was looking for! Thanks!

-

Sorry to revive an old thread, but did anybody come up with a way to visibly tell the difference between a 15-gal and a 20/21-gal tank? The owner's manual shows my 94 as supposedly having a 21-gal tank, but i have NEVER been able to put more than 13 gallons in it after driving on E for a day or so! I'd like to know if any junkyard tanks I pull (or order) are indeed a 20+ gal model! Thanks!

-

I'll add, when testing the injectors for resistance, make sure the terminals on the injectors are good and clean before you rule them out as faulty!!! I "had to" replace two injectors, well, once I had them out, and scraped the terminals with a flat screwdriver, magically they showed the proper resistance!

-

Pulled crank pulleys off damper, help me line up marks please!

peejay replied to 93pathyfiend's topic in The Garage

I think each mark is 5-degrees apart, so if the leftmost mark is 0 degrees (Top Dead Center), each additional mark is 5-degrees BTDC (0-5-10-15-20-25-30) Good luck! -

And make sure your EGR valve isn't stuck open!

-

EGR Function Check Engine Light problem.....? RESOLVED!

peejay replied to leeuniverse's topic in The Garage

Thought I'd share some pics of the EGR Diverter (Nissan parts calls it a "TUBE GUIDE"). Thanks to all the contributors to this post, it helped me out ALOT, i mean, COMPLETELY!!! First pic shows the diverter location, note the arrow points up. Second pic shows the valve all clogged up! NO exhaust was gonna be recirculated into the intake!!! Third pic shows the valve somewhat cleaned (and all the gunk that came out of it! I used a small flathead screwdriver, shop towels and brake cleaner...a round bristle/bore brush probably would've worked better). -

Thanks, Slart... I'm waiting to thaw out from the "Snowmageddon" (ice) here in Atlanta...I should be able to re-run the tests for EGR Function as outlined in the FSM, then I'll report back to you. Having a PROPER understanding of how that solenoid works this time should help me out, I hope it's as simple as a clogged EGR valve, but I need to make sure I'm getting vacuum to the valve, when it's supposed to! (i replaced the 3 EGR vacuum lines not too long ago, one was suspect, and just did the others off GP!)

-

Slart... you...are...the...man! didn't know a circuit can be switched to behave as positive or negative! (but I still got the CEL, might need to PM you if that's ok!)

-

Slarti, Thanks for the response! The part about "...vacuum would remain in the line, and the valve would remain open..." reallys clears up why there is an "A" and a "C"! I have but "one last question"...according to the FSM, the EGRC solenoid should receive a ground signal from the computer at 2,000 rpm, and that vacuum should exist at the hose leading to the EGR valve ("B")...this leads me to believe the computer is calling for EGR at 2,000 rpm, which means the EGRC solenoid is allowing vacuum to lift the EGR valve at this rpm? And that under 2,000 rpm (or at high RPM), the computer does not send a ground signal to the EGRC, so that the solenoid does not admit vacuum to the EGR valve? I tested this on my engine, with the voltmeter connected to ECM terminal 104 (for EGRC), battery voltage starts appearing at 2,000 rpm, and returns to near zero at idle... is something wrong with my EGRC solenoid? or is my ECM sending a ground signal at the wrong time? That is, it should be sending the ground signal at rpms of less than 2,000 or greater than, say, 4000?

-

Hmmm...have you tested the injectors for leakage? Will it start when warm/hot if you give it some accelerator pedal?

-

Thanks for the response Slartibartfast! I think the FSM has it wrong here, again... On page "EF & EC-16", it says of the EGR Control (EGRC)-Solenoid Valve, "The EGR system is controlled only by the ECM. At both low- and high-speed revolutions of engine, the solenoid valve turns on and accordingly the EGR valve cuts the exhaust gas leading to the intake manifold." And on page "EF & EC-21", it says "...When the ECM detects any of the following conditions, current flows through the solenoid valve in the EGR control vacuum line. This causes the port vacuum to be discharged into the atmosphere so that the EGR valve remains closed. 1) Low engine coolant temperature 2) Engine starting 3) High-speed engine operation 4) Engine idling 5) Excessively high engine coolant temperature 6) CPU malfunction of ECM and camshaft position sensor malfunction" However, the diagnostic/test procedure indicates that the EGRC solenoid is "normall" closed/off, and becomes energized under certain conditions (engine speed at/above 2,000 RPM, wheels in motion)...and the FSM tests would indicate that the EGRC solenoid actually OPENS when energized (by the ECM) to allow vacuum to flow through the solenoid and to the EGR valve, to OPEN the EGR valve, allowing exhaust gas to enter the intake...so instead of the system cutting exhaust gas when activated, it seems like it admits exhaust gas when activated... I still don't get what the port "C" is for...why does the solenoid need two inputs (port A & port C)? Why am I not seeing vacuum at the hose that connects to the intake boot?