-

Posts

221 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Calendar

Everything posted by cham

-

Thanks guys, based on research something like this does sound like it can be anything from a bad coil to the IACV. What I should mention is like I’ve said this has been going on seemingly since I owned the car. It has gotten slightly worse over the years but was always there in some capacity. I’ve cleaned the MAF sensor close to 5-10 times over the years. I’ve taken apart my IACV to replace the gaskets as a preventative maintenance for that dreaded coolant leak issue. I guess the IACV itself could still be bad. When I replaced my PCV valve and spark plugs I cleaned my throttle body and reset the Idle relearn procedure after assembly (drive by cable). Now I do believe there is a potential vacuum leak somewhere possible from my assembly of the plenums but this didn’t affect the vibration post assembly. Vibration remained in the same capacity before and after that job. I should say since I did that job of replacing the spark plugs etc i started to get P0420 and P0430 codes and have yet to address. My assumption was since they started right after I did the work they are likely being triggered because of a vacuum leak or a bad ignition coil etc something I moved around while I was in there. Takes about a month for the code to come back usually. No misfire codes or O2 sensor codes. I have noted stumbling though when at idle right after a hard drive on the highway if I gun it pretty hard. I definitely think I used too much dielectric grease when installing the spark plugs but I see no misfire codes. Ever since those codes started showing up my gas milage has been terrible. I’m going to get a smoke test done soon on the intake and exhaust just to rule those things out as there’s more than likely a few leaks here and there regardless of what I have touched. Should I stay away from those Firestone places for something as simple as a smoke test haha? There’s one near me that has been pretty good with the manager being a classic JDM guy who’s owned them all. Not sure what the mechanics are like though I’ve only had an alignment done by them. Sent from my iPhone using Tapatalk

-

I’ve been dealing with this for a long time; I understand the basic reasons this might be happening but I’m hoping in providing more specific details I can narrow the scope, also hoping somebody has dealt with this exact issue. With the vehicle warmed up, when in Drive or reverse while stopped and idling the whole vehicle shakes. It doesn’t really start until a few seconds after coming to a complete stop and the RPMs fall and settle slightly below 750rpms (around 650rpm). When idling in park or neutral the RPMs are dead at 750, no vibration or shaking. Certain things like using the window regulators or turning the steering wheel while stationary will additionally make the whole vehicle shake and the rpms drop slightly. Now the shaking is pretty aggressive, turns my seat into a massage chair and it’s been doing it seemingly for years. I’ve always thought it was the transmission but it’s lasted tens of thousands of miles like this and shifts beautifully now. I’m starting to think it might be the alternator (never been changed) not supplying enough output to my battery (new) but I would think that should effect the vehicle at idle in park and neutral as well. I think another likely candidate is the IACV crapping out and not reacting correctly when coming back down to idle with a load placed on the engine (in Drive). I’m sure it can be my torque converter going as well but what I’ve noticed is when the car starts to shake and vibrate at a stoplight for example (in Drive), if I turn on the Air-conditioning or heat, the rpms bump up briefly to between 700-750 and the vibration immediately goes away. Then as the ECU gets used to the additional load it settles the rpms back around 650 and the shaking/vibration comes back. Seems to me like maybe the load on the engine at idle in Drive is too much somehow causing the engine to bog, or should 650rpms not cause my car to shake? Whether it be a failing alternator or not enough air getting in through the IACV, the revs drop because the load is slightly too much. In every other case there is no vibration once the revs are at or above about 700rpm. What do you guys think? Sent from my iPhone using Tapatalk

-

I would go with factory plastic valve covers, you'll likely spend an equivalent amount trying to source the aluminum ones. The originals lasted a good amount of miles in my case and in your case 21 years. The problem with the spark plug tube seals is the act of removing the old valve covers to change the gasket usually does them in even if they weren't leaking before. Like @hawairish said, the spark plug seals are not serviceable unlike the aluminum covers.

-

Rear springs that don't sag but don't raise the car too much?

cham replied to EricCR's topic in 96-2004 R50 Pathfinders

I found myself in the exact same situation as you about a year ago Eric. I ended up going your initial route with the rear OME MD springs (2922) and it improved so many aspects of the vehicle I never regretted it. Now I personally kind of like the raked out look combined with the fact that I carry a lot of gear on weekends heading to the mountains it seemed like the perfect solution. Well I will say after installing the MD springs just in the rear, it was too stink bug looking even for me, I didn't let it stay like that for long. With likely sagging front springs as well, the disparagement was too much so after a couple months I decided to put MD springs in the front too. For a while I debated whether to actually do the Light Duty springs over the MD because I liked the raked look. Well I'm very glad I didn't, so much so I also added the Rocky-Road front trim packer with my MD springs because I wasn't happy with just the MD springs up front. Even after the springs settle, with just MD in the rear I think it would be too much of a difference. When people say 2" lift, that's from the sagged out state. It's 0.75" of lift over the stock from the factory height. I'd recommend actually just going ahead and doing the OME 2922s in the rear for now and when the funds permit go with the matching springs in the front. You won't regret it and in the meantime the handling of your Pathfinder will feel like new. Despite what people say, worn out springs also have a huge contributor to body roll and polar moment of inertia. My guess is if you went with a factory like replacement for example from Moog, you'd wished you had gotten a lift. -

Got both axles in and there definitely seems to be a slight increase in vibrations over the worn out factory axles (I get a foot massage from the gas pedal now lol) but I can live with it and I don’t feel like going through that again and sending axles back etc. Kind of wish I just rebooted an OEM axle from a low mileage junkyard Pathy but ah well. If the vibrations get worse I might do that. Do CV axles have a break in period? As for the differential side axle oil seal; did not go so smoothly. Once I had the passenger side CV axle off, I removed the four axle end retainer bolts. I then proceeded to hammer away at the flange from every possible angle with everything under the sun and it never budged. To make things worse I believe when you hit the flange you are applying a direct load on the inner race of the axle bearing where the shaft collar mates to it. The side axle wants to slide out with its pressfit collar and with the flange but the retainer is keeping that from happening (the retainer houses the bearing) thus potentially damaging that side axle bearing. So for anyone in the future attempting this; I’d highly recommend a slide hammer and be careful not to be too rough. Or if you do it the old school way; plan to replace the axle bearing and everything else that goes with that assembly. I just said the hell with it; the leak isn’t too bad and bolted everything back up. Last thing I promise; got a P0430 code that comes and goes seldomly but my gas mileage is in the tank. Any change it’s just an O2 sensor in bank 2? I have a BlueDriver can I determine a bad O2 sensor based on live voltage data? I replaced my spark plugs a few months ago and maybe used a little too much dielectric grease on the ignition coils; worried the electrical contact is not the best it could be. I do not have any missing codes though. Sent from my iPhone using Tapatalk

-

I think just seeing the transfer case move that much up and down when I leaver on the rear driveshaft surprised me a little. But as far as I can tell the 3rd member bushing is not thrashed. Yes I do mean radially. If you grab the flanges and apply up and down impulses there is slight radial play in both output shafts in the Transfercase. I guess the rear shouldn’t be too surprising since the driveshaft yoke actually slides into the transfer case; it’s not bolted; so of course there is some clearance. I’ll check the OEM CV axle today to see if it’s rotating concentrically or not when the wheel/tire is at full droop. If so, I might send the new CV axles back as I don’t want to cause more vibrations than I already have to deal with. On the drive home it didn’t seem too bad but I wasn’t able to get up to highway speeds yet so not sure if the vibration is worse or not with that new driver side cv axle in. They are “Value Select” Nissan axles by the way, definitely a little more expensive than your average aftermarket axle so I would assume some decent quality. Without being on sale they are about $250 an axle. Usually you can find it on sale though around $180. Sent from my iPhone using Tapatalk

-

Got my front driveshaft worked on and installed. They replaced one u-joint as it was quite notchy and had no intentions of loosening up with some hammer persuasion. Had it rebalanced as well. Most of the vibration is gone but there is still a very slight oscillation vibration that comes and goes above 70mph. When putting it back in I found that my transfer case front output shaft and rear output shaft flanges have a very small amount of lateral play. If I leaver up on the rear drive shaft I can also make my transfer case move in its 3rd member bushing but I checked the bushing and it’s still pliable and not torn. I’m guessing there is an allowable amount of movement. Got one of the new CV shafts put in today and it had zero binding with my OME MD coils and Rocky Road Outfitters spacer. The only issue I noticed is when the tire is off the ground, and I’m spinning it while looking at the CV axle; the center shaft of the CV is rotating ever so eccentrically instead of concentrically. In terms of driveshafts you could say the cv axle has a lot of run-out if that makes sense. I still have the original OEM CV axle on the passenger side so I’m going to test that function tomorrow. I’m just curious if that is normal and a product of CV axles needing to move inwards and outwards to articulate, therefor the center shaft doesn’t spin exactly concentrically and with zero run-out. Sent from my iPhone using Tapatalk

-

I see I was just confusing viscous for meaning wet for the clutch packs. I know how a viscous coupling works since they are pretty cool mechanical marvels. The fluid is shear-thickening so non-Newtonian and when used in tandem with a center diff, if the driveshafts experience a differential in RPMs the fluid induces a lot of friction and tension in the housing as the alternating plates spin past each-other but there is no "clamping" force with a spring, the fluid creates all of the friction between the driveshafts. What's interesting is when taking corners the required difference in driveshaft speeds is marginal and not enough to really engage the coupling which prevents wind up so its a perfect solution right?! Well I think the main drawback with them is they can have a propensity to lock up over the years and they also can have a delay in engagement but depends on the system and whatnot. Some manufacturers make them have a more aggressive engagement while others make them softer which aids in delaying their engagement. So much so that some manufacturers I think VW Sycros system literally preload the viscous coupling for faster engagement but at the cost of wearing tires faster from sometimes excess tension in the drivetrain. I think I was applying the mechanical nature of the viscous coupling to the multi-plate system which doesn't makes sense since the wet multi-plate clutch doesn't have a mechanical reactive nature like you said; it needs to be told by a computer exactly what to do. The nature of the viscous coupling is completely reactive based on the properties of the dilatant, so i guess I should say hydro-mechanical nature. What I'm still trying to conceptualize is how either system can simultaneously apply torque/power while still allowing slip (so gassing it into a corner; or slip occurs while gassing it). In one scenario, you want there to be slip to keep from windup, in the other you want the slip to stop. So for the wet, multiplate clutch (which is what the manual calls it), since it's like a manual clutch in a trans, you wouldn't simultaneously apply slight clutch pressure and then give it gas because that would just wear the friction material. When you down shift you rev match but that's literally to get the two shafts spinning the same speed or close enough. I guess I can only think of it as locked or unlocked in my head. Could it be doing just that; slip lock slip lock but just at insanely fast intervals? Or is it more likely the plates are constantly slipping past each other but even that slipping has friction between it thus transmitting torque and power? Edit: This guy makes the claim that the All-mode is essentially switching the transfercase into 4 HI when slip occurs and its just constantly going back and forth between 2H and 4H to prevent driveline binding/wind-up. Sounds like they don't know that power is sent to the front in other conditions such as when applying more gas. They could still be right though as the system watches wheel speed sensors so if it detects the front axle wheels spinning faster than the rear axle wheels; it might switch back to 2WD in that moment. That would solve my confusion about simultaneous torque delivery and slip when gassing it into a corner; because that would mean its just in 2WD in that scenario. Link to forum thread: https://forums.nicoclub.com/auto-mode-always-4wd-t548182.html

-

Thanks for the page reference I’ll check that out for sure. So I’m still a little confused about the whole “wet clutch” thing because wouldn’t that be the same as a viscous clutch pack? Is it a derivative of a multiplate clutch like the Nissan GTR Atessa system uses? So I get how the system is electronically modulating the clutch engagement in Auto. So what if you’re applying power into a corner; does it separate the clutches to allow the front wheels to spin faster than the rear or will it still slightly engage the clutches to transmit power to the front wheels since you are “accelerating” but also allows slip of the clutch so that there isn’t any binding. A center differential in the end can achieve the same thing; you just lock the diff and the front and rear driveshaft are locked at a 50:50 distribution and in fact I would claim it’s a stronger system since it’s actually locking bevel and pinion gears together with a pin instead of a wet clutch. The problem is when it’s unlocked, only one wheel needs to loose traction for the entire thing to lose forward momentum unless there is some addition engineering aid i.e. viscous coupling or multiplate clutch or electronic wizardry. So when we are in 4H the wet clutch is fully “locked” as you say but is it actually locked or just held together through friction of the plates and can still potentially slip? Edit: Yikes just saw the T-case oil filter service in the manual. It’s $230! Any chance you might be able to just remove it and clean it and throw it back in? At this age should we replace it haha my T-case does produce a little bit of a whine now days. Sent from my iPhone using Tapatalk

-

How does the ATX14A T-case transfer power in the Auto setting? I think I read it doesn't just send power to the front axle when slip is detected but also progressively the more you accelerate. Sounds like it might use a "viscous clutch pack" instead of a viscous coupling which I believe are slightly different. So theoretically if one wheel slips not all power is siphoned to that one wheel. This would happen in a a fully mechanical center differential like found in early 80 series LCs before they started adding a viscous coupling. Also when you lock the transfer-case in 4H, are you actually "locking" it per say or is it just spinning up that viscous clutch pack to "mimic" a locked center differential when in reality nothing is actually "locking" the front and rear driveshafts, its just a lot of friction in the clutch packs holding the shafts at similar RPMs?

-

That’s right I believe a lot of Semi trucks have their axle bearings bathed in gear oil rather than grease. Funny enough I actually do have that needle zerk adapter in the form of this Mountain Bike Park Tool lol, I was thinking this would work pretty well vs my normal grease gun. I did actually notice around the same time my rear axle oil seals are also leaking but only very very slightly, almost unnoticeable. At the same time, that means it’s probably the best time to replace the oil seals before the gear oil washes out the bearing grease and ruins them. Sent from my iPhone using Tapatalk

-

Yeah I think you’re right on the money. That inner oil seal is definitely failed as the gear oil is what I’m seeing leak at that seam. It remains to be seen whether the grease seal is also failed or not; let’s hope the grease seal is made of the same class of polymer or something similar that’s resistant to gear oils otherwise the oil might be eating away at it once it made contact. I’ve also heard (at least for wheel bearings) some people let their axles leak into the wheel bearings and give them a gear oil bath; I think it’s mainly done on 80 series and 100 series land cruisers if I remember correctly because the axles leak so much. Obviously a diff axle and hub wheel bearing assembly are different but I believe in our case both are the tapered style bearings. Theres also the possibility even if I see oil leaking past the front side of the grease seal it’s not the end of the world as it was only meant to hold grease back and something like gear oil being less viscous might be able to leak past pretty easily. I think what I’ll try to do is check the condition of the grease seal and with the side axle removed, try to lubricate the backside of that axle bearing if there is an opening to do so. I’m worried about degreasing it when I’m not actually cutting the collar and removing the bearing. If I can only get grease at it from one side I likely won’t be re-greasing the entire internals of the bearing. So supplemental grease without degreasing would be ideal in my eyes. Unfortunately a cold chisel, slide hammer, and axle press for the new collar are not apart of my toolset and I would be worried about screwing it up if I tried and alternative tool on such a crucial component. Also I might have confused you with the FSM, I’m not dropping the diff just getting at those seals since I will have my CV axles off when replacing them. From what I can tell there the side axle should come right out without needing to open the diff case up at all. It’s just those bolts holding the extension retainer on. Sent from my iPhone using Tapatalk

-

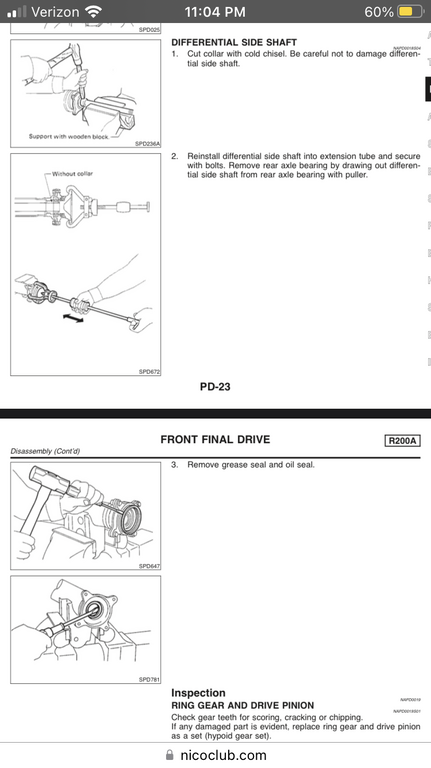

Ah I see now; the side axle comes out with the extension tube retainer, bearing, and grease seal still attached. If I wanted to get at that grease seal I’d need to cut the collar and do exactly as the FSM states with the slide hammer. Don’t trust myself on that one with a “cold chisel” so I guess I’m only replacing the oil seal now. I would think that the oil seal is what is leaking the majority of the gear oil whereas the grease seal just protects the axle shaft bearing. Any reason you think it’s absolutely necessary to take the extra step and cut the collar? For example maybe the gear oil has contaminated the axle shaft bearing and now I need to degrease and re-grease the bearing etc etc

-

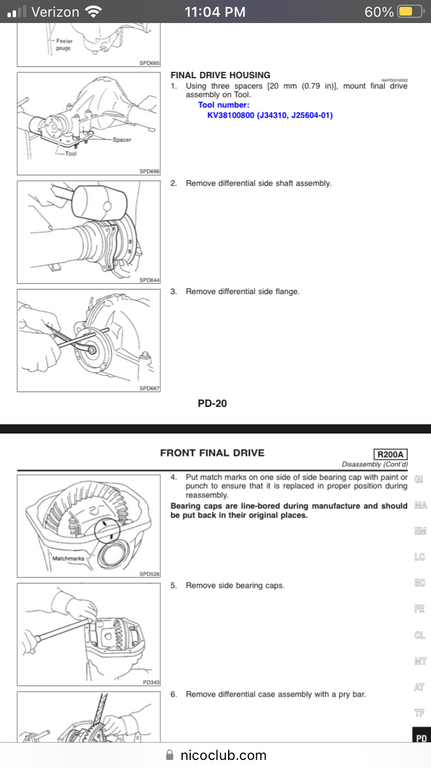

That’s right; that rear grease seal will have a gaping hole for grit ingress. I think for that reason Im just going to swap the axles and forgo that test all together. So I also decided to order the front “final drive” differential side axle seals as the axle end seam behind my passenger side cv axle is leaking gear oil. This includes a grease seal and oil seal. So I’m looking at the FSM and it’s not making any real sense on how to remove the side end axle for the the front diff. As you can see in the photos it shows removing it with a mallet and then later shows hammering off some collar and then using a slide hammer to remove the side axle but it was already removed with the mallet. Confused if it’s just showing multiple ways to do it; also what’s with hammering a collar off? I was thinking of just using a rubber mallet for disassembly and installation. Concerned though about what the collar’s purpose is. Sent from my iPhone using Tapatalk

-

Was VDC the traction control system that was supposed to mimic lockers? I believe 03 and 04 MY are the only years to get it of the R50 generation. To my knowledge I do not have it as I can spin my wheels pretty easily if I get crossed up when crawling. I'm going to go with the Value Advantage and see how it goes. I'll check for binding immediately after installation at full droop before I put any miles on them as well. The warranty is only for a year but it seems like a no questions asked type deal unlike some of the parts store special stuff. Plus I probably won't be with this rig but so much longer. I'm also guessing even if these are rebadged aftermarket I would think Nissan would have the forethought to heighten its quality control on what they allow to be sold under their name unlike most aftermarket parts stores. Lastly these should be as close to the original OEM axles in terms of dimensions, so I would think getting those Rockford Dura Thermoplastic Boots would fit no problem if ever need be. Couldn't say the same for the "Extended Travel" offerings which I seem to be hearing a lot of boot failures with normal driving. As for the remaining vibration its only barely noticeable now without my front driveshaft in so my guess is its a combination of my front CVs being worn out and my rear driveshaft U-joints also beginning to show their age. I mean even with the front shaft not seeing constant torque like the rear; those factory u-joint needle bearings had been churned into dust when I disassembled them; I can only imagine what the rear look like at this age.

-

Sorry no the TrakMotive Extended Travel is only about $150 sold on RockAuto but I have read reports of them actually failing. The Napa version of the Extended Travel design is $350 despite them looking identical to the TrakMotive version so who knows what's actually going on. I'm assuming the Napa version is made with better materials and tolerances but it could simply just be a huge markup. I've only got the Medium Duty OME Coils all round and the 3/8" trim packer (Rocky Road Outfitters Spacer) on top up front. I've read people with more lift and no problems so I'm just going to have to do more investigation. Any chance I might be able to remove my cv axles and drive with out them? Since the wheel bearings are preloaded on the steering knuckle stub axle; removing the cv shouldn't effect that I'd assume.

-

Removed the front shaft and the vibration at 50mph and above 70mph is much better, but unfortunately still there to some degree. On the U-joints replaced around a year ago for the front shaft; there is binding in a couple of the cups so its not surprising the vibration got better. The vibration is still mostly felt in the pedal so my assumption is its the cv axles since installing the lift made the vibration worse. The only problem is I jacked the front off the ground and when spinning the wheels there was zero binding for both the driver and passenger cv axles. If a cv axle isn't causing any binding; can it still be the source of a vibration? (Also I forgot to mention my tires are only a few thousand miles old and I had them rebalanced the other day just to rule that possibility out)

-

Yeah I think I also read something along those lines about the Nissan Value Select being rebadged aftermarket for like a Nissan Altima CV axles. Regardless it seems all the aftermarket stuff are a crapshoot whether it will bind or not and last. I know there are some “Extended Travel” options out there now offered by Napa and O,Reily’s etc; is that the extra ROM you were talking about? I don’t think they’ve been around long enough for anyone to get real opinions of them yet and it seems the same manufacturer is supplying the parts for all of the “extended travel” brands from what I can tell. As for the vibration; maybe my CVs are worn out enough to where the extra lift (MD Springs with Trim Packer) is just enough to make them somewhat bind and cause the vibration. Most people seem to not have issues with binding though until they’re running like 0.5”-1” spacers on top of stiffer coils. I guess the way I'm seeing it is my original OEM axles are likely 220k old so even rebuilding them with new boots and grease means they are at the end of their life even being the best quality OEM. I don't even think the original OEM are sold by Nissan anymore; only their Value Advantage Line. I'm thinking of either going the NVA or O'Reilly's ImportDirect Extended Travel option "NI8185ET" being that many people seemed to be okay with the normal "NI8185" axle. If I had the funds I'd go with the Napa ET options but at $350 an axle; its considerably more, especially when the design looks identical to the Oreilly's ET and TrakMotive ET designs. The price difference must be in the materials and manufacturing/quality control.

-

Thanks Bart you seem to have the answer to most of my inquires I do appreciate the insight. Yeah it certainly is a pain diagnosing vibrations and at this age throwing parts at the driveline and suspension isn’t necessarily a bad thing. The front shaft has the annoyingly contrived C style Circlip snap rings instead of the end cap snap rings and is a pain and a half to install without any binding. I used Spicer Red Box which is the best you can get aftermarket for our front shafts and even after installation the vibration was still there (I replaced them initially not just because of a vibration but a clicking coming from the shaft). Took a trip to Colorado where I used 4WD a lot (at high speeds too) which seemed to get rid of a lot of the vibration but still remained. Fast forward to new tires and a lift and now I’ve got a vibration exactly at 50mph and above 70mph that feels kind of cyclic. It could honestly be my cv axles as the inner boots just tore from the lift and I have no idea as to the condition of my front diff bushings. I think I’m going to go with the Value Select Nissan CVs as Ive heard so many woes with the aftermarket brands. I’ll take out the front driveshaft as well and see where I’m at in terms of vibration. Any experience with value select parts?

-

Hope you all are well, So what’s the deal with the All-Mode ATX T-case pump. Seems a while ago someone found out through the FSM that the “Main Shaft” rotates a pump in the T-case that lubricated the T-case while driving. Sounds like someone confused the “main shaft” for the front shaft and assumed manual locking hubs would not work for that reason. But then it was decided that the “main shaft” in the FSM is actually referring to the rear drive shaft; can anyone confirm this? I’ve replaced my front driveshaft U-joints about a year ago and still get a vibration (and before anybody asks, the vibration did go away initially when I took the front driveshaft off to diagnose). After getting new tires and a lift it seems worse so I’m planning on taking the front drive shaft off again to diagnose if the vibration goes away. I’m assuming it should be fine with all of the people running manual locking hubs on their all mode pathys, this essentially replicates that condition (although the cv axles and diff are still spinning). My plan was to get the front drive shaft balanced if the vibration goes away when I remove it but technically it could still be the cv axles or differential (driveshaft connects the diff to the T-case which could be what transmits the vibration to where I’m sitting). So even if I remove the front shaft and the vibration goes away; could it still definitively not be the driveshaft causing the vibration?

-

Just bought those top hat rubber insulators myself for my lift about a month ago with a discount at my local Nissan dealers website. Shipping is free if you ship to the dealer. Don’t go nissanpartsdeal, they overcharge and take forever plus I’ve had bad experiences with trying to return stuff that came damaged. It’s just one rubber seat underneath the tophat (54036) in the exploded diagram. I believe 54036 and 54057 are one unit or possibly welded because when the struts are disassembled they have always been permanently affixed from what I can tell. As for what you need to replace, well that depends on you. Don’t replace anything metal as those parts should be totally functional unless you live in the salt belt but even then they should be fine. At the most you should replace (54050M) strut boot, (54034) rubber insulator seat, (54325) strut bearing, (54329N) top plate gasket, and (54034NA) coil sleeve. Now my 0.02, I had to replace my strut boot because it was degraded but not necessary if yours is fine. (54329N) can be cut out of cheap paper/cork/rubber gasket kits found at your local auto parts store. Now as for the coil sleeves I never understood why it showed one at the top and bottom as the coils are flat ground at the top anyways so you couldn’t fit one around the top coil. Mine never came with one. Therefore you only need one for the bottom and that’s if you really want it. Most people do not replace the coil sleeve on the bottom. I said what the hell and got these nice Eibach ones with adhesive on the inside to keep it adhered. Part#: Eibach CS5002L they work a treat and I believe they come out cheaper than than the factory ones. Other than that I’d order a clamshell coil compressor design from Amazon it makes the job a hell of a lot easier. Trick is you can send it back once you’re done and get your money back since their return policy is so good.

-

Thanks guys yeah your assumptions were correct I ended up having to re-tap all 4 upper bolt holes for M12-1.25 which I enjoyed immensely being on the ground underneath. I guess I was surprised because the original stripped hole came from a corroded frozen bolt ripping out the hole threads using an air impact when disassembling where as the others were just giving way while assembling. Almost looked like helicoils in the holes from the factory when I was drilling it out but I digress. Still only torqued to 40 ft-lbs because of my fear of it happening again; also got rid of any evidence of antisieze as well but I'm confident now this was not the source of my front end clunk. Cheers guys!

-

Few years ago I was replacing my sway bar bushings and I stripped one of the upper bracket bolt holes. Years later I finally decided to get around to fixing it. Tapped some new M12-1.25 threads (original are M10-1.25). When assembling I decided to unbolt the other side bracket to add some anti seize to the bolts just so this doesn’t happen in the future. When torquing to spec (46-65 ft-lbs) I started stripping another upper bolt hole. What gives!! I believe the original stripped when I was removing the bolt because of how corroded everything was (the bolt took the hole threads with it when un-bolting) but why are other fasteners stripping when I’m just torquing to spec (set to 55 ft-lbs)? Anybody else have similar issues. 1.25 threads sound a little fine for this kind of load to me. Could the antiseize be lubricating the bolt causing overtorquing?

-

Well I finally got around to securing the driver side exhaust heat shield again and this time with a stainless steel zip-tie. To my surprise no change, the rattle is still clear as day and I’m at whits end at this point. I feel like I’ve checked every damn heat shield on that vehicle. My next best guess would be to swap to a 40 weight oil and see if that quiets down the rattle at all; if it does i have my answer unfortunately. If not I could try resetting the ecu and running premium gas for a couple weeks to see if it’s pinging for whatever reason; anyone know the best way to reset the computer before filling up with premium? My last guess would be the accessory belt pulley bearings; how difficult is it to retention both belts after removing because they aren’t automatic tensioners.

-

Been a little while so I'll provide a quick update. I ended up bending that driver side lower exhaust manifold heat shield down and then out for better access. I decided on some JB Weld Heat Weld Epoxy. Seemed to do the trick at first and initially I thought I had completely fixed the rattling noise. Couple days later the noise was back but in a less obvious way and in even more limited circumstances (it may have never completely gone away in the first place). I then decided to take another look at that passenger side engine mount heat shield and figured out a way to secure it with a hose clamp underneath against the actual engine mount itself. No more rattling on that heat shield when knocking it with my hand. Days later I heard the rattle again destroying my confidence that I could ever make this rig reliable again. Eventually I took another look at the manifold heat shield repair and what to you know the JB Weld had failed allowing play again. The plan now is to just use a metal ziptie around the manifold and heat-shielding, hopefully that works. Side note; I'm curious if wrapping a hose clamp around the upper heat shield plate of the engine mount and the lower base of the engine mount would transmit more vibrations because since doing it I cant tell if I notice vibrations at 50mph and 70mph more now. I already know my driveshaft u-joints need some love (replaced my front-shaft u-joints myself but the shaft still obviously vibrates; should have gone with a fully rebuild shaft).