MarkRobinson

-

Posts

39 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Calendar

Posts posted by MarkRobinson

-

-

I am on my second nissan SASd rig, and both had low pinion 44s and neither used a double cardan shaft. I've never had an issue with slip yoke length nor yokes binding. I like using the first gen xterra shafts.

As to which axle to run, I'd go with the F150 axle, only because it's full width. Staying narrow never appealed to me personally.

Finally, I'd do a true 4 link in the rear. A panhard bar adds complexity and causes a bit of rear stead that isn't necessary if you triangulate the ; links properly.

-

I haven't been on here in a while, but thought I'd post a pic from our first wheeling trip last weekend. This is a climb at Golden Mountain Park in Sparta,Tennessee. I was pleased with how the rig did.

Hopefully now that I've gotten my wife and little one out in the woods, we'll start going more often.

-

3

3

-

-

Are you going to have to cut the front output off the front case and do a filler plate? I've seen it done with NP231/241 and BW cases so I imagine it can be done with the tx10 too

-

I think they used it as they stated it was built for: as a camera/chase truck. It went places, but was never used as a wheeler.

I know it had mud in crazy places and scratches all over the paint.

They just left the door wide open to make it better; nobody took time to tune it properly .

-

14 bolt front and forget it. Cheap, hell no - the last axle you'll ever need? Oh yeah!

-

Looking sharp!

-

Hmm. I have been into them for a long time.

I used to own a SASd frontier maybe 6 years ago, then parted it out to build a pathfinder buggyish thing that was scrapped because it was too rusty to be worth the effort. I then built a samurai based buggy that I found was just a huge lawn ornament 95% of the time. I parted it out and sat on a dream to build a maroon 1995 5 speed pathinder, when low and behold, I found the one I own now.

Anyway, I mentioned Labor Day at WITC to the wife and she likes the idea.

-

Did I sell you some wheel spacers a few years back? When I parted out my frontier I sold some to a guy somewhere off of 231 who drove a champaign pathfinder.

Keep an eye out for me. I'll be mall crawling down to shelbvul for a wedding tomorrow.

-

Might have to. I've actually not had it out wheelin' yet. I have driven it as far away as Atlanta.

Where do you live?

-

-

I guess I jumped the gun posting this.

It's an 18x26 cookie sheet. It should fit our radiators well with some persuasion. I found that you can get 1" core radiators for the pathfinder, so I'm going to pick one up and do the swap then. Ironically, it's too dang hot out to do it now.

-

Sure was! Can't wait to do it again some day.

On to my next project. The pathfinder came with a decent electric fan (not sure what it's from but it looks like a single speed version of the big taurus fan people use), but no shroud. It's just mounted right to the radiator. The wiring is good and it's tied to the ac circuit, but it gets hot. I added water-wetted and it helped but I need a proper shroud.

Look what the brown Santa just delivered from Amazon:

$14.99 and it's just a touch too big so there's room to cut it down to fit.

-

Barry! Remember me? I drove the maroon frontier to Moab a few years back.

I sure remember you:

Barry: What are you doing?

Some guy: Stacking rocks.

Barry: I'm just gonna drive around 'em.

-

Today I replaced the old busted console, with the lid that stayed open so you rested your arm on sharp plastic. The one I picked up is from a 2001 isuzu rodeo.

I had to rework the e brake handle. I raised it about an inch and welded it to the floor plate about 1.5" off center.

This console feels great on the elbow and has cup holders! It just took a long time to figure out mounting.

-

2

2

-

-

Personally is fake out the overload. I bet that's costing you flex, plus leaving your 3 working leaves will keep ride height close to what it is now.

-

When I had 63s under my frontier, they were weird. They started super tall and settled a bunch with driving. They flexed great though.

I believe I had the 2 leaf pack from a half ton truck.

-

Congrats on getting out and doing some riding!

Were you riding with the sway bar disconnected? It looks like the front wants to use up its flex before the rear.

Mine was sort of like that in reverse. The leaves were stiff until the 4 link rear was almos flexed out. Added a rear sway bar that stays hooked up and now they flex at about the same rate.

-

I didn't snap a pic since it was dark when I finished, but I put on a marlin crawler pitman arm today. Man, what a difference! Much more positive steering; I'm not chasing the rig all over the road.

-

Thanks.

That pic of the suspension was taken at the same time as the next one, with the rig flexed out.

At ride height the sway bar is nearly level. It points up perhaps 10 degrees but nothing drastic. It made a world of difference vs when I didn't have it.

-

-

I didn't take many build pics, but here's what I came up with for a crossmember to catch my lowers:

That's the repurposed hitch that came on the truck.

After completing the truck, I found it needed a sway bar desperately. It wasn't near as bad as the stock setup that it replaced - that thing could have rolled itself in a parking lot. Oh, and as for springs, it had some 280 lb rusty's springs that were too stiff, so I swapped them out for some JK front lift springs my buddy Jimmy at Essentially Offroad donated.

Here's the finished setup. I used a stock sway bar, but moved the axle end mounts inward from the stock location, effectively making the sway bar weaker than stock. My goal was a setup that didn't need disconnects; tame on the road, and tame on the trails.

As you can see in this flexed out pic, I placed my poly bumps to where at full compression they keep the tires 1" out of the wheel wells. I have dreams of 37 13.50 r17 Toyo Open Country MTs in a couple years.

This is last recent pic I have. Its yesterday, in Northern Alabama at Little River Canyon. We packed her up and went for a little weekend jaunt and had a blast. We didn't do anything that even resembled wheeling, but I'm tickled. On road manners are great, although I still see room for improvements. I ordered a Marlin Crawler Toyota drop pitman arm that showed up while we were out of town; that will quicken my steering and get some of the modest bumpsteer in check.

-

2

2

-

-

This post is going to be brief and full of pics. I tried posting from my phone and the page timed out. I was posting from my laptop and closed the page when I was almost done.

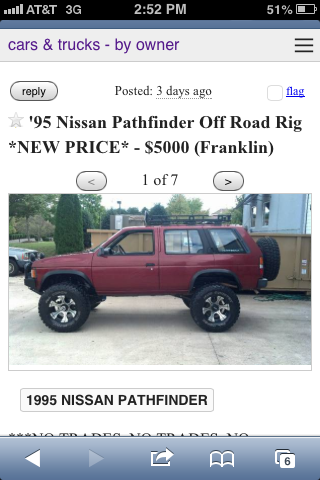

Here's the craigslist post that started it all. I was searching for a new pathy for my wife and stumbled on this ad. We struck up a deal and were on our way to Franklin, TN to RTM Productions to pick her up. I have a trailer and truck but figured, eh, what the hell, lets take her down the interstate:

After bringing her home I found a whole laundry list of things I wanted to fix:

- Too tall

- Too stiff

- Tires hit body

- Bumps too close to axles (to combat the tires hitting the body)

- Factory 5 link rear sucked

So I pulled out a leaf in the front packs and redrilled the mounts to move the axle an inch forward, cut down the coils, and cut off the bumpstops.

The rear steer characteristics and wheelbase with the 5 link meant it had to go. So, I began a triangulated 4 link

-

1

1

-

-

I just finished a 4 link rear on my pathfinder and love it. I used jeep Cherokee rubber bushings and 1 1/4" heim lowers and 7/8" heim uppers.

If you take your time mapping it out you can get great performance from a link setup, without the wrap associated with a leaf setup.

I'll be adding a write up on my journey with my rig soon.

I bought a HP Dana 44 again and some parts, then got smoking deal on a waggy 44, decisions!

in Solid Axle Swaps, Hardcore Custom Fab

Posted

I meant single cardan. One u joint at each end. Pinion relatively flat, parallel to transfer case output.