-

Posts

40 -

Joined

-

Last visited

Content Type

Profiles

Forums

Calendar

Posts posted by Willfly4money

-

-

I just rebuilt my trans about 2k ago, search my posts if you want to see it. The rebuild kit is cheap but as I'm sure you've seen in the manual, other critical parts aren't so cheap. I have never priced the reverse housing or the sun gears but I'll bet that the best route would be a donor trans from junkyard. Obviously a complete takedown of your trans is in order with a lot of emphasis on the valve body's and debris. One of the biggest pains that you have seen (since you have your trans out already) is taking these massively heavy transmissions out of the truck!! Good luck and FWIW, you don't need a lot of special tools aside from clutch spring compressors (I used c-clamps and brute force), but if you follow the manual, it will tell you if high tolerance components need to be replaced as well as runout/end play checks needed.

-

Finally got the pump out of my transmission after viewing this video which helped. It might help others.

Here is one image of my reverse drum showing wear in the area that slides over the pump. I think the material in there was brass. The steel on the pump shows no damage. I suspect this is where the failure of no reverse is coming from.

Also, all friction plates look very good with lots of material remaining, however I will replace them all since the transmission is apart now.

I can't quite see the pic that well but if the bore of the drum is damaged, you need more than just a master rebuild kit I believe. If your reverse clutch plates are intact then you have another problem as to why reverse isn't working. Did you follow all troubleshooting as per the FSM before removal of tranny including the ECU check with the light in the power/Econ switch on the dash? Also perform all the solenoid resistance checks as per FSM. The bore in that drum has channels that port pressure to the reverse clutch to engage it, if it is blowing by then it will not work, keep in mind that the drum you are referring to has more than just the reverse clutch in it. If ALL clutch packs are good then you must look elsewhere; valve body, solenoids, bore clearances etc. good luck and have fun!

-

Just do a google search for wd21 FSM it's been so long I don't remember exactly have me the link. Once you have it, become very familiar with it and life will be easier with your pathy! Rebuilding the transmission was fun and I'm thinking about doing it on the side when I'm not flying, too bad you don't live nearby.

-

1

1

-

-

I just disconnected my rear driveshaft when towing, front hubs unlocked wont even spin the CVs.

-

I have a RE4R01A from a 95 pickup that needs to be rebuilt. I believe that when it was last rebuilt that the temp sensor and switch were not replaced as it went out less than 3 months after having new solenoids installed. Let me know if you find the electrical parts. I found the solenoids from WIT in orlando florida. WIT (Whatever It Takes) really good source for trans parts and cases to.

See post above, make sure to test the electrical components to make sure that is your problem before you do anything.

-

Amazon is telling me the NM-20 doesn't fit my Pathy (1991 4x4 SE). Am I looking at the correct part? Should I just ignore Amazon and chalk it up as them not knowing what the hell they are talking about?http://www.amazon.com/ATP-NM-20-Automatic-Transmission-Master/dp/B004QBZXOW/ref=au_pf_pfg_s?ie=UTF8&Make=Nissan|67&Model=Pathfinder|893&Year=1991|1991&carId=001&n=15684181&s=automotive&vehicleType=6

Also where do I get the solenoids, temp sensor, and the temp switch? Mine was rebuild December of 2011 and it's shifting all wrong and slipping in all gears but not all the time. I suspect my issue is with the electronics in the trans. I bet they didn't replace any of that when they did the rebuild.

Hello, sorry to get back so late! I've been out of the country for three months. Yes the NM-20 is what you want. Wait until you test the solenoids and temp sensors as per the book before you buy them. They aren't cheap and they may be just fine. Go by the book and perform all the troubleshooting and testing matrices before and after the rebuild, it will help you to understand what exactly is wrong. Our trucks have a built in test system for the tranny, the procedure is there in the book and you can find out if an electronic problem exists or not.

-

1

1

-

-

I once thought I had an EGR temp sensor code, (pretty expensive part!) but I quickly found out that I was reading the code wrong LOL, it was actually an injector circuit code....

-

Here is a cheap route.

-

2

2

-

-

Sorry, I don't have a terrano manual but fwiw, a VG-30E 4WD pathfinder with 4.625 rear end is supposed to lock up at 64-69 mph at half throttle. The book only gives lock-up/ lock-off values at full and half throttle, thus, during troubleshooting you must run the truck at those throttle settings to find anything. I wish I could help but I know nothing about diesel terranos.

-

Hi, OP!

Can you share where you got your rebuild kit and the rest of the replacement parts you used? I looked in Amazon but can't find it. Someone local is selling a no-reverse tranny which I'm thinking of buying to rebuild. The one on my Pathy has the same no-reverse issue.

Thanks!

Sure thing!, search amazon for the: ATP NM-20 Automatic Transmission Master Repair Kit

It should be around $150. You will need to buy an internal filter from wherever you choose as well as a brake band, I would suggest rockauto on those two items. If you have a 4x4 MAKE SURE AND ORDER THE NM-20 kit as opposed to the NM-21 or NM-22 as these two are for other tranny codes (cars or 2-wheel drive).

The best you could hope for is that the friction plates on the reverse clutch is the only thing wrong, in that case the master repair kit will fix your problem. If it is a valve body issue (stuck shuttle valve or screwed springs) that isn't a real expensive problem either as the manual has the part numbers for the springs and if a valve is stuck you can just clean out the valve body and reassemble with new seals/gaskets. Just keep in mind, if the tranny is out of the truck and sitting in front of you, NO MATTER WHAT IS WRONG, I would strongly consider rebuilding it with this $150 kit while it is out. The reason I say this is that these trannys are not fun to take out and even if the only problem seems to be the valve body and associated shuttle valves and springs (or solenoids for that matter), you are MUCH better off pulling the guts out and freshening it up. If one set of clutches has "grenaded" that means the friction material has traveled through a good portion if not all of the tranny, so a complete tear down is in order IMHO. Again, while the tranny is out of the truck, it is astronomically easier to just follow the manual and quickly disassemble and rebuild so as to make it fresh. The caveat is that if any of the solenoids or the temp sensor or the temp switch are bad, that will increase the price significantly, but I will say that in my opinion, these electrical items have a low failure rate.

Here is my understanding of the extremes: As long as the tranny in question has not been heated to the point of actually warping the parts listed on page AT-201 of the manual, the rebuild is pretty straightforward and shouldn't require much more than what I stated above. If you have any questions along the way I would surely help as much as I can.

-

1

1

-

-

The reverse clutch and the high clutch are in their own clutch pack so I can see how loosing one would contaminate the other. I'll try to go easy on third.

-

I'm curious as to how it shifts. The stock shifts are normally hard 1-2, long soft 2-3, and a "normal" 3-4.

I'm glad you asked this question! It does shift stock with a hard 1 to 2 and a soft 2 to 3 and 3 to 4 is what I would call normal.

Regarding the 2 to 3, I think third gear is kinda funny on these trannys, from what I gather, third gear is 1:1 and requires all forward clutches to be engaged (could be wrong on this) thus it takes the highest volume/pressure of fluid in order to "lock" without slipping. My background is airplanes which usually have a gearbox with one speed so I could be wrong lol. Anyway, I think third gear seems to be a weak point in our RE4R01A trannys in these year models. What say you?

-

Good to know1

I like your rigging it with what you had on hand. Good job!

I didn't want to try to patch into the sensor so I went with an analog 2" gauge. It fits perfectly in the plastic to the right on the 94-95 models. There is a thread on it and filters as well pinned in this section IIRC...

It almost looks factory and doesn't clutter up the dash.

B

Thanks for the post, I read that one and you're right, that looks pretty good. I'm going to mount my digital guage below the aftermarket radio I have and see how that works.

-

Here was my rear main, I believe this was stock and you can see it was leaking a little. The only other major leak I have is the drivers side valve cover.... Should have done that one when I did head work about 5 months ago!!! I'll learn one of these days.

-

If you think that's a lot of plates, the newer RE4R01A that's in the Xterra's and Frontier's have even more.

Yeah I'd like to get a junkyard xterra tranny and build it up in the future, I just had to get this truck back on the road for a decent price and so far it has only cost $150 or the rebuild kit, $150 for new torque converter, $40 for fluid, and about $20 for a new brake band and internal filter. I went ahead and did the rear main seal which was about $13.

-

I didn't want an analog tranny temp guage taking up space on my dash but I also didn't feel like paying big bucks for a digital guage so I used this device that I had on hand from my RC plane stuff: http://www.hobbyking.com/hobbyking/store/__9744__Hobby_King_Voltage_Temperature_Monitor_2_6S_0_150C_.html

It is a combination voltmeter and temp sensor, it uses an LM-35 type sensor and it is closed loop (no body ground needed). Most of all, if it fails, it only cost 8 bucks!

I took an extra tranny drain plug, drilled a hole through it and used permatex ultra copper RTV to install the sensor into the center of the drain plug. I ran the wires through the shift boot and hooked the voltmeter up to the cigarette lighter circuit and finally grounded the unit to the fuse box. The end result is a small digital readout of system voltage and tranny pan temp. This device also has programmable alarms for temp and voltage!

-

One problem I saw with the stock thermistor temp sensor is that taking a "constant" reading from a thermistor requires a CONSTANT reference voltage and as we know on these vehicles, the alternator output varies with electrical loads, so using the stock temp sensor with a voltmeter is only so accurate.

-

Are you going to put an auxiliary cooler or in-line filter on?

Thanks for all the pictures, very interesting!

I put an aux cooler in series with the stock cooler but haven't gotten around to any filter options yet.

-

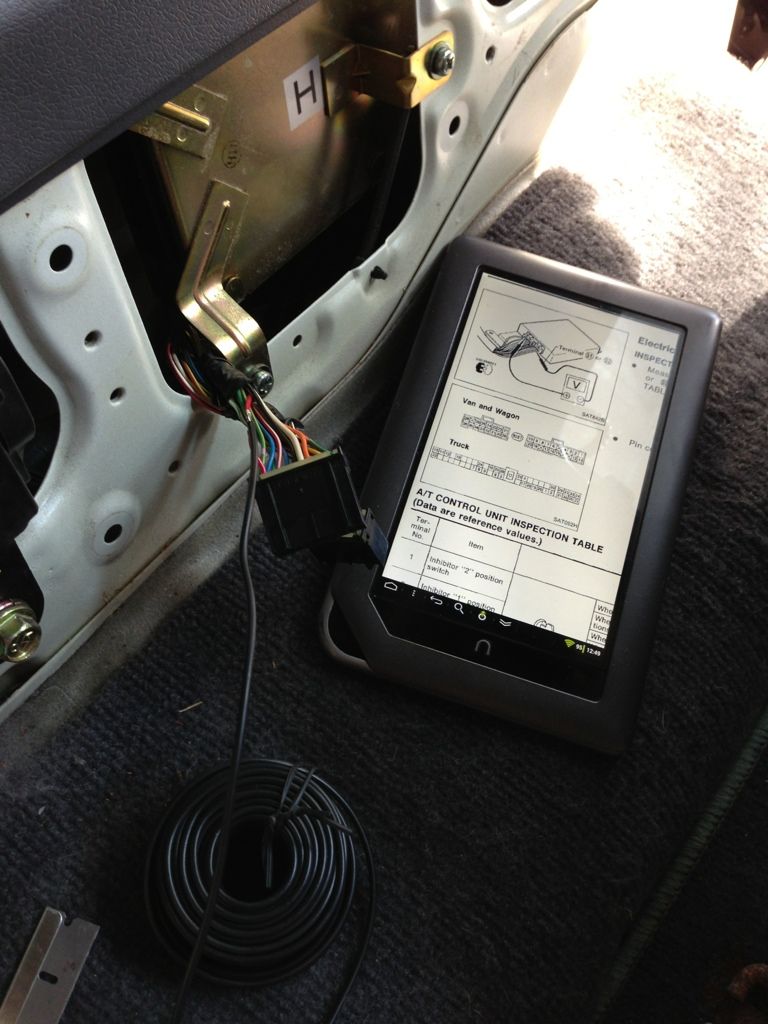

After the install, I wanted to be able to monitor the fluid temps to see if anything went wrong with the rebuild. Our tranny has a thermistor type temp sensor from the factory that feeds the tranny computer. (there is also a temp switch located beside this thermistor which actuates the dash light for the tranny over temp) So for a quick fix I tapped into this input here at the computer.

The manual states that this thermistor will cause the voltage on pin 12 to be 1.56 volts at 20c and .45 volts at 80c. I just hooked up a voltmeter to this line and went driving.

The highest I saw after putting the tranny through a rigorous workout wast 190f (through interpolation), although I am fine with seeing up to 200f at the pan, I went ahead and installed a Hayden tube and fin cooler I had on hand. More tests will follow.

-

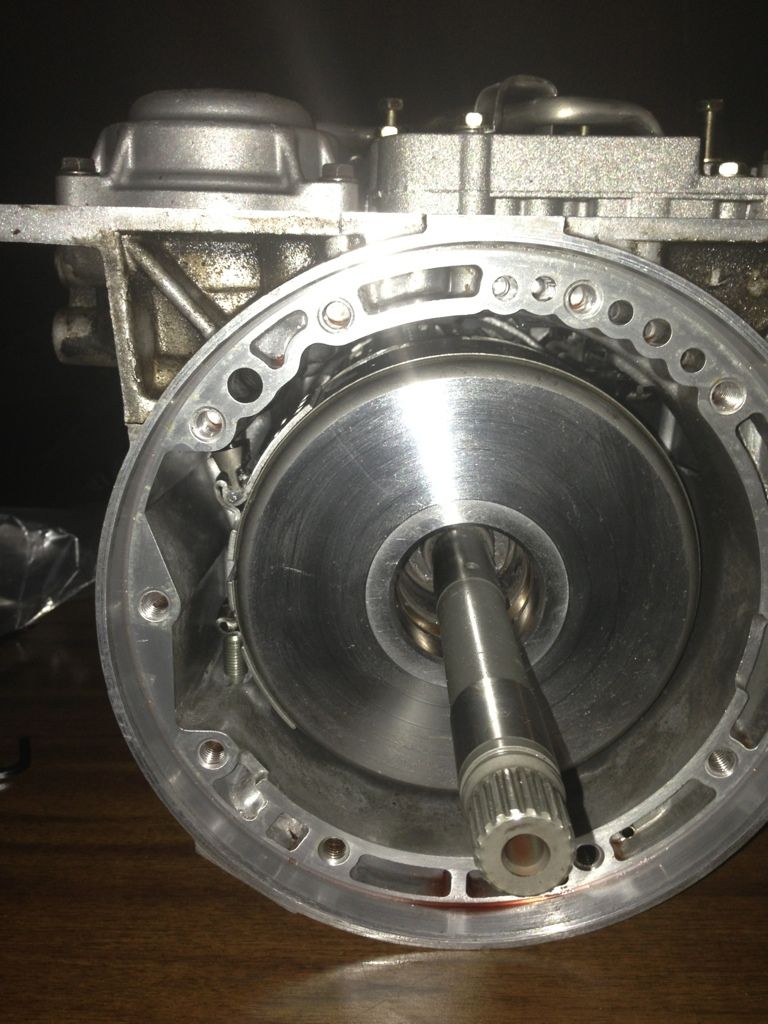

Fast forwarded, all ready to install!

-

The reverse and high clutch pack installed with the new brake band from rockauto, the master rebuild kit didn't include a brake band or an internal filter.

-

Thanks for all the praises everyone, I wish that I had taken more pictures along the way. The tranny is back in the truck now and has 200 miles on it and she is doing pretty good. Precise1, I don't know what happened but I can now see all the pictures. I'll continue posting the pics that I have.

Here she is going back together. One of the tricky parts is getting all the needle bearings in their rightful place, I forgot one during the assembly and had to take half of it apart.

I can say that in hindsight, rebuilding the tranny on the table was fun BUT taking it out and putting it back in was not fun in the slightest. I just hope this thing lasts a while!

-

Checking the gap after the new plates.

-

There are this many plates in a 4X4 RE4R01A!!

Look what I found in my transmission

in 90-95 WD21 Pathfinders

Posted

Yeah, a shift kit would be a good investment if you've got the funds. The stock pattern seems to be a hard 1st to 2nd with a soft 2 to 3 and a "normal" 3 to 4. On my particular trans, the soft 2 to 3 ended up cooking 3rd clutch. I have wanted to stiffen up the 2 to 3 shift since my rebuild but my motorcycle and job have taken precedence...

The FSM has a matrix that shows which clutch (and when the brake band) is locked in any given scenario, this answered a lot of questions for me. The later trannys were improved upon but there are shift kits/improvement kits that can bring our "old" gearboxes up to speed. I went with just a rebuild due to the low cost and hope to use it for a good while, I have an okay aux cooler as well as a temp gauge with alarm for when I'm pushing my trans.