missionstreet

-

Posts

30 -

Joined

-

Last visited

Content Type

Profiles

Forums

Calendar

Posts posted by missionstreet

-

-

Yes I had that recall done. Dealer Seemed reluctant to take my 23 year old truck in for free body work. They used plates and did some kind of bedliner on the whole area both side front fender wells.

Paperwork said it was ~700 total in the body shop.

-

Thanks for that - Any suggested points of interest?

-

Thank for that response. I'm still trying to wrap my brain around how the front suspension can affect the rear sway.

-

I'm referring to the infamous "roll over" sway that was supposedly caused by rear control arm bushings. The rear starts to sway uncontrollably at highway speeds.

I put on the OEspectrum by monroe in the rear.

-

I cant see any wear or play in rear pan hard rod, maybe I need to remove it to see for sure?

I didn't think front control arm bushings could contribute to rear sway? I'm not getting sway up front. Tires have some outer wear but only up front. Alignment is good.

-

On my 98. So I got moog replacement upper rear arms and pressed in new bushings for the rear lower arms. Did torque with wheels on ground, full tank of gas, truck empty.

Of course the sway is nothing like it was before (couldn't go over 45~50).

Well I still have death sway intermittently sometimes around 45 and 60 and in-between. Not as bad but still can build up like a harmonic enough to scare a woman.

Also have new shocks and sway bar links and ends. Thinking maybe coils next?

Someone save me from throwing too many parts at it.

Thanks!

-

On my 98. So I got moog replacement upper rear arms and pressed in new bushings for the rear lower arms. Did torque with wheels on ground, full tank of gas, truck empty.

Of course the sway is nothing like it was before (couldn't go over 45~50).

Well I still have death sway intermittently sometimes around 45 and 60 and in-between. Not as bad but still can build up like a harmonic enough to scare a woman.

Also have new shocks and sway bar links and ends. Thinking maybe coils next?

Someone save me from throwing too many parts at it.

Thanks!

-

Actually just crawled under there to address some rear sway stuff and honestly it doesn't look that hard to get to for me. I think its sitting behind an exhaust support bracket.

I did wiggle the wire to the connector as I was soaking the bolt and I noticed OD not flashing anymore on start up.

-

I finally got to this and I can't tell if these ring/cup is supposed to detach from the sway bar link bracket. Dont have a picture now but there are rings on the other side of the bushings and then ones on the bracket that look stamped on but I could be wrong.

The links I got by moog are not what rock auto images showed.

This link below from advance auto is what I got exactly. Look like self tapping zerk grease fittings. Eggish shaped bushings...Guessing the tapered bushing ends go towards each other??

https://shop.advanceautoparts.com/p/moog-stabilizer-bar-link-k80435/21880144-P

-

Thanks all, just now able to get around to fixing this. Have P0500 and truck seems NOT to be in transmission limp mode and shifting OK (I have even been towing). Will check flash sequence later today.

Reading about a possible plastic gear that fails and is NOT included with new sensor? That's of course after you manage to remove the old crusty sensor from transfer case. Thank God I broke, torched and extracted all those bolts for the exhaust heat shields + bracket that holds the harness plugs while I had it on a lift replacing the rear brake lines...

-

Im getting a bunch of fast blinks from the "OD disable" light in my cluster every time I start the truck. All fast flashes. Coincidently the speedometer is no longer working.

I don't believe the transmission is in "fail-safe" or "limp" mode as I can see/feel it shifting through gears.

Anyone experienced this?

-

Soon to replace to those links. Meanwhile I'm wondering what the physics of the bushings is in relation to the sway. Is it the lateral force mainly that a stiff, good bushing guards against to stabilize the rear?

-

I have LT tires, will look into the panhard rod bushings and new rear sway links. I'm just wanting to be sure I don't "mask" the problem with other new suspension components.

When loaded, it feels like I'm having the same swaying problem before any control arm bushings were replaced.

-

The shocks are brand new. The weight back there is really unequally distributed right now. I'm really eager to get a trailer but now I still have this stupid sway problem!

-

I just finished replacing all 8 bushings in the rear control arms along with new shocks. I used stp (not sure if this was good idea) to help ease the bushings into the arms along with the help of a 60 ton press. Concerned there might be slippage since the stp doesnt "dry" after application.

Now I still have bad sway at low as 35-40mph over bumps, albeit the truck is loaded with a small generator, steel ramps, tool box, 2nd spare, big and small floor jack, couple 2x4 light fixtures, and a bunch of other junk back there.

I had initially done the lower arm bushings 2 years ago and that resolved the problem 90 percent UNLESS it was heavily loaded in the rear.

-

Turns out it was an exhaust shield rubbing the driveshaft

-

1

1

-

-

To my amazement I found the long sections running from pass wheel to rear available by pickup for less than $100 from a local dealership (shipping would have been 300+ more via freight due to length).

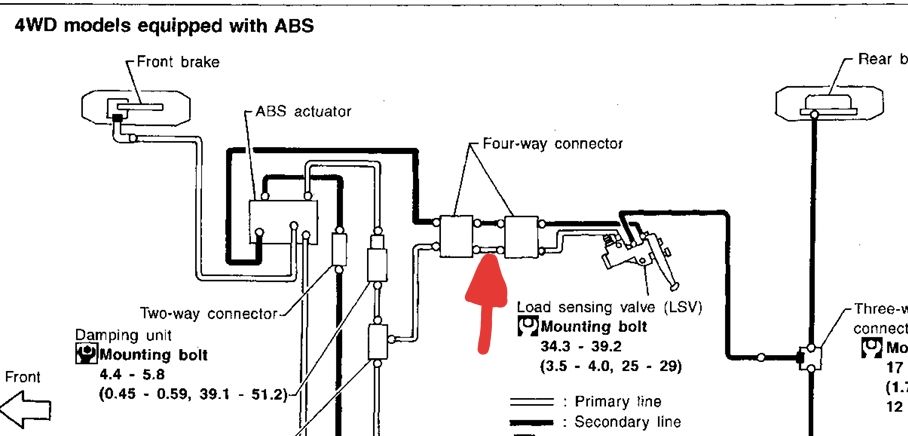

After replacement and initial bleeding (including load valve) per FSM I'm getting very firm pedal with engine off but once started pedal is going to the floor, albeit stopping good by the time it reaches the end of its travel.

I figure there's still alot of air to be bled but I can't understand the extreme discrepancy between having power assist and not. I also noticed (its dual circuit 4WD) one of the lines to the rear was completely empty and dry when I disconnected it. I believe it's the one coming through a splitter block off the master and not through ABS.

-

I had to pull my rear pass brake drum to disconnect the ebrake cable and after putting it all back together there is a horrible rubbing scraping sound. I've thoroughly cleaned all the rust off the channel on the drum and the backing plate and it's pretty quiet rotating the wheel off the ground but as soon as its driving its noisy as heck. Hub feels fine, no play. I've moved the self adjuster out to just barely contacting the drum. Anyone encounter this problem? Thanks

-

Yeah I've got the FSM and the connector section shows something back there I think, not sure if it's that plug. I've seen in Chrysler FSMs entire sections showing every single plug.

-

-

Looking for a connector for trailer lights on my 98 (built in 97). I see a connector rear passenger side on the frame rail near bumper, does anyone have any info on that plug?

Thanks

-

Yes, it spans between the two lower control arms, directly beneath the steering rack.

-

So I was looking to jack my front end up and grabbed the big cup floor jack. Used a 4 inch piece of 2x4 between cup and member DEAD center (I measured it). Stopped before wheels were barely off the ground as I had a feeling I should use a longer piece of wood (3x3x8).

Did I possibly do any harm? How strong is it? Thanks in advance.

-

When you say shear off do you mean just meant to be cut?

I guess if the bolts snapped off at worst I'd be riding around with no rear anti sway? Until I could make new threads since you can't get a nut up in there?

Compatability help please

in 96-2004 R50 Pathfinders

Posted

Does anyone know if a 2000 pathy quarter and rocker panel will be the same shape as a 1997?